As the world searches for an alternative to traditional fossil fuels in the transportation sector, hydrogen is emerging as a viable alternative. If the potential of hydrogen is to be realised as a transportation fuel, the components that make up the systems must be of the highest quality...

Safety

Security is of prime importance for plants that are part of so-called critical infrastructure, such as water and power supply, telecommunications, and chemical...

The recent cyber attacks on plants in the process industry emphatically underline the fact that such attacks can cause considerable financial, health and other...

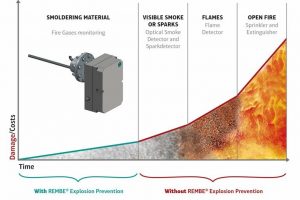

The handling of bulk solids poses many challenges. One of these is the enormous amount of dust that is created by conveying and processing the different...

Rico has launched the next generation of the proven Ventex explosion protection valve. The valve now features a flow velocity of at least 30 m/s in all...

Spectrex announced the launch of its next-generation Sharpeye 40/40D and C series flame detectors that provide optimum protection against hydrocarbon-based...

Safetyinsight, a suite of digital software applications, helps businesses in the process industry manage their process reliability across a system’s entire...

The SR series – in durable stainless steel – comprises more than 30 enclosure sizes to meet the precise dimension requirements of every intended use. To...

Evidence of the integrity of pressure vessels is imperative in guaranteeing the safe operation and availability of chemical plants. TÜV SÜD shows how...

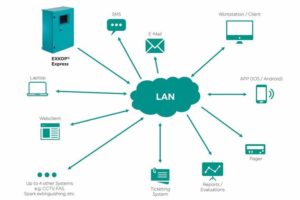

Visualisation of safety-relevant faults in the control room are only half the battle. In order to appropriately react to such faults, pre-defined counter...

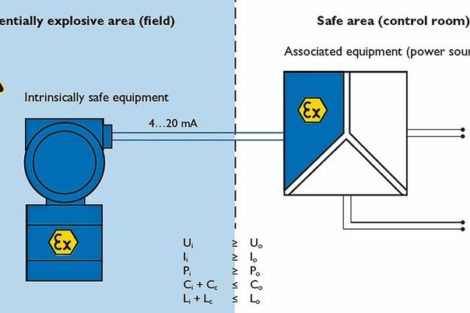

Functional safety is highly important in the petrochemical industry, as it is in general in the process industry. Even insurance premiums for operators are...

With GEA Remote Support, GEA experts are instantly available via video, which neither requires pre-installing software nor an updated IT-infrastructure. GEA...