Filter systems represent a central point in most industrial systems because the air extracted from the various machines is usually bundled and guided through a pipe or exhaust duct behind the filter elements. Precise monitoring of fire gases within this pipe or exhaust duct enables fire incidents to be detected at an early stage not only in the filter but in all connected machines and system parts.

Fire gases develop before smoke or flames can be recognised. Depending on the bulk material certain fire gases arise earlier, later or only to a limited extent. In order to cover exactly this point, Rembe relies not only on the measurement of carbon monoxide (CO) but also on hydrogen (H2), hydrocarbons (HC) and nitrogen oxides (NOx). In this way, monitoring can be set flexibly and precisely to the process and the material.

Advantage of fire gas monitoring

Fires usually develop over a long period of time. Nevertheless, temperature rises in the exhaust air can be detected very late by means of temperature sensors and conventional smoke detectors are too sluggish and dust-prone for the use under industrial conditions due to their functioning. By the time smoke concentrations can be detected, a fire has usually already spread too much. In contrast to this, the GSMX-P follows the approach of detecting fire gases in the formation phase and thus does not have to wait for strong smoke concentrations or late temperature increases. If the gas concentrations deviate even slightly from the target state, the GSMX-P already gives a first alarm. Depending on the process conditions, 100 g hot product is sufficient to represent a reproducible detection.

Mode of operation

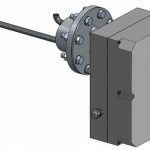

The GSMX-P fire gas detector monitors the entire cross-section of the clean gas or ventilation line. For this purpose, it is attached to the line in a separate housing. Two pipes protruding into the clean gas or ventilation line generate continuous air extraction over the entire cross-section using the Venturi principle. The design not only enables representative and reproducible monitoring, but also dispenses with further electrical aids such as pumps or fans.

Almost every process in every industry can be monitored with a GSMX-P in a filter. Because it is a complex system for monitoring multiple gas components, factors such as the following are considered:

- Air flow rate m³/h

- Flow velocity and pipe diameter

- The amount of dust in the air

- Bulk goods (fire and explosion parameters)

The sensor is installed in the process and gets used to the process and the conditions in the first step. This makes it possible to create an exact picture of the conventional gas concentrations to then find the optimal limit value for each application. This is usually just above the conventional concentrations in order to detect even the smallest deviations and to prevent a fire.

Rembe GmbH Safety + Control, Brilon

Author: Alexander Kemmling

Sales Executive Explosion Prevention, Key Accounts D-A-CH,

Rembe Safety+Control