Syntegon has recently developed its own calculation model based on so-called Life Cycle Assessments (LCA). The method allows the company to evaluate energy consumption and emissions during the entire life cycle of its machines.

Pharma

Clariant has completed the acquisition of Lucas Meyer Cosmetics, a leading provider of high-value ingredients for the cosmetics and personal care industry...

Eppendorf has joined forces with Neste, a leading producer of renewable fuels and feedstock solutions for manufacturing polymers and chemicals, to advance the...

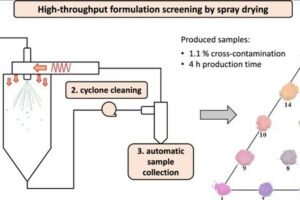

Researchers at the University of Chemistry and Technology Prague have unveiled an innovative spray drying robot, designed to change the pharmaceutical...

Emerson has collaborated with Sartorius to natively integrate Sartorius’s Biostat STR Generation 3 family of bioreactors with Emerson’s DeltaVTM...

From 26 to 28 September 2023, numerous international experts in mechanical processing, bulk solids and conveying technology will once again gather at Powtech...

„Together for Sustainability“ is a good title for the Endress+Hauser Global Forum 2023. On the occasion of its 70th anniversary, the measurement and...

Clariant is set to expand its Care Chemicals facility in Daya Bay, Huizhou, China, to boost its support for pharmaceutical, personal care, home care, and...

The Dencytee Arc sensor from Hamilton Bonaduz presents a new generation of in-line total cell density biomass measurement. Unlike the conventional measurement...

The Thermo Scientific Ramina process analyser offers non-destructive and continuous analysis without the need for sample preparation, with rapid system setup...

De Dietrich Process Systems is expanding its range of turnkey plant extraction solutions to cover all steps in the extraction of cannabidiol (CBD) and THC. In...

GEA’s kytero single-use pharma separator convinces with its high separation efficiency, the simple and safe handling, gentle product handling and the...