Researchers at the University of Chemistry and Technology Prague have unveiled an innovative spray drying robot, designed to change the pharmaceutical industry’s approach to drug development. This research, led by František Štepánek, marks a leap forward in the quest for faster and more efficient pharmaceutical formulation development.

Pharmaceutical drug development relies heavily on the creation of amorphous solid dispersions (ASDs) to enhance the dissolution rate and stability of active pharmaceutical ingredients (APIs). Developing ASDs with the desired physico-chemical properties is a complex and time-consuming process that often involves the manual preparation of numerous sample compositions with varying ratios of API and excipients. This tedious and resource-intensive task has hindered the systematic exploration of formulation design space, resulting in suboptimal formulations and slower drug development processes.

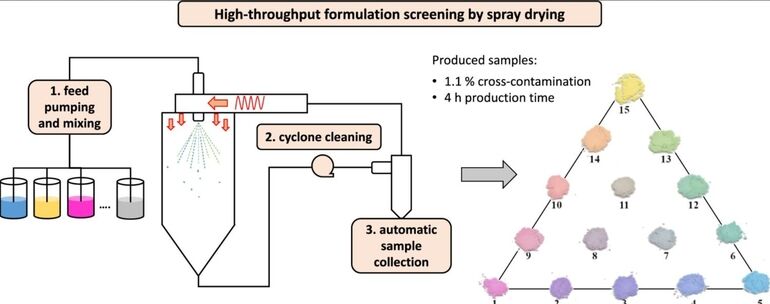

František Štepánek‘s team has addressed this challenge by introducing the spray drying robot, an innovative device that streamlines the preparation of ASDs. The spray drying robot leverages a commercial laboratory spray dryer, enhancing it with three key components: a computer-controlled feed mixing and pumping array, a cyclone cleaner to minimise cross-contamination, and an autosampler for automated sample collection. This combination allows researchers to produce powder samples with systematically varying compositions during a single spray drying run, reducing the time and manual effort required for formulation development.

Accelerate pharmaceutical drug development process

The significance of this breakthrough lies in its potential to accelerate the pharmaceutical drug development process. By automating the creation of multi-component powder samples, the spray drying robot offers a practical solution for large-scale screening studies, allowing researchers to explore the formulation design space more efficiently and systematically. This time-saving innovation will significantly contribute to the development of superior and more effective drug products.

Notably, this research marks a practical limit on the achievable resolution in the composition design space. With the ability to select from up to nine different feed solutions and assuming a conservative composition resolution of 20 wt%, the spray drying robot can generate up to 1287 distinct powder compositions, potentially rising to 43,758 with a 10 wt% resolution. While not all of these formulations may be meaningful, the spray drying robot empowers researchers to conduct formulation screening studies with time savings, minimising the risk of missing out on superior formulations.

Research article: Vojtech Klimša, Gabriela Ruphuy, Jan Jonáš, Lucie Mašková, Ondrej Kašpar, Pavel Žvátora, František Štepánek, Spray drying robot for high-throughput combinatorial fabrication of multicomponent solid dispersions, Powder Technology, Volume 428, 2023