Clariant and Duslo’s research institute Vucht are transforming waste into wealth. Using a proprietary technique and Clariant’s Hydex E next-generation hydro-dewaxing catalyst, Vucht has successfully converted plastic waste into premium winter fuel distillate. The efficacy of this process has now been proven in a pilot plant in Slovakia. As plastics and fuels are both mainly composed of natural gas or crude oil, turning one into the other has major implications for sustainable and lucrative fuel production.

Stefan Heuser, Senior Vice President & General Manager at Clariant Catalysts: “Upgrading gas oil fractions to more valuable products has become essential for improving refinery economics. Clariant is committed to supporting this customer need through innovations such as Hydex E. We are honored to partner with Vucht in their pioneering plastic waste-to-winter diesel technology, and very pleased about the outstanding performance of our next-generation catalyst in the process.”

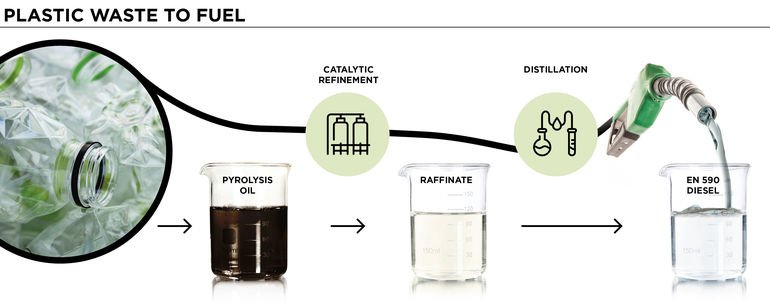

Vucht is part of Duslo, a Slovak producer of fertilisers, specialty nitrogen compounds, and rubber chemicals. The institute uses a pyrolysis process to convert a variety of plastic waste collected in the country (such as polyethylene, polystyrene, polypropylene and PET) into diesel fuel. The process thermally degrades the plastic at temperatures above 300 °C, converting it into liquid oil comprised of various hydrocarbon compounds. Recently, the institute developed a proprietary technique to further convert the liquid oil into a high-quality fuel distillate known as winter diesel.

The winter diesel produced is compliant with Euro 6 fuel emission standards, including cold flow properties specified for temperatures as low as -34 °C, typically required in arctic areas. To achieve this extreme improvement in cold flow, Clariant’s Hydex E hydro-dewaxing catalyst was applied. After intensive pilot testing proved the technical viability and economic appeal of the process, Vucht is planning to expand the method’s success in a custom-built demonstration plant with a fuel distillate capacity of 40 t/a.

Hxdex E is an selective isomerisation hydro-dewaxing catalyst specially developed for highly paraffinic feedstocks. The key advantages of this zeolite-based catalyst are that it has the ability to significantly raise fuel quality and yield, while minimising costs and by-product formation.