Alfa Laval and Bisviridi, part of the BioteCH4 Group, the UK‘s leading biogas plant operator, are working together to increase the recycling of organic food waste. The partnership will combine Alfa Laval‘s Prodec-Oil-Plus decanter with anaerobic digestion to convert oil and fat waste into biofuel. This process, developed by Bisviridi, produces bio-crude oil.

Bio-crude oil can be refined into sustainable aviation fuel (SAF), which meets the decarbonisation goals of the aviation industry and opens up a new market. Lee Dobinson, Chief Commercial Officer of Bisviridi, highlights the value of the partnership and explains: „The volatility of oil prices in recent years and the need for large biodiesel companies to find new sources of sustainable waste oil streams has led us to develop a way to utilise this waste.“

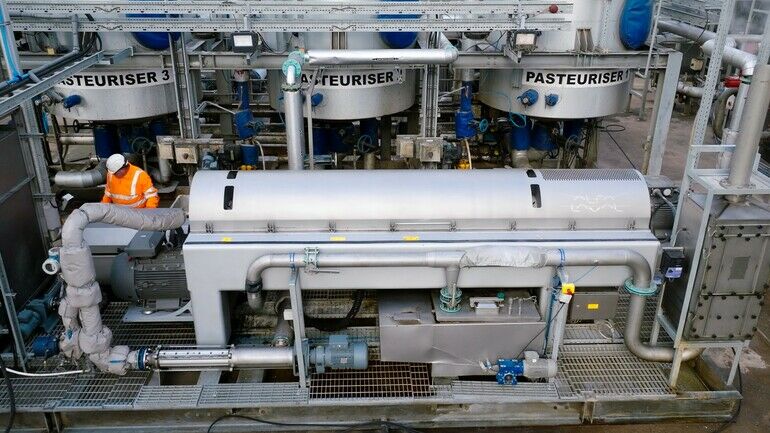

Decanter is a key component

The Alfa-Laval-Prodec-Oil-Plus decanter is a key component in the Bisviridi process, can be seamlessly integrated into any biogas plant and offers numerous advantages. Prior to methanogenesis, the decanter extracts oils and fats from the organic waste. The remaining components can be fed back into the fermentation plant; the impact on biogas production is minimal. The resulting bio-crude oil has a purity level of up to 99.5%, making it an ideal feedstock for refineries to produce biofuels for the SAF market.

Thanks to the latest collaboration with BioteCH4, the biogas plant can achieve a considerable production capacity of up to 300 litres of oil per hour. The design of the decanter ensures easy operation and maintenance. It is available as a stand-alone component or as a plug-and-play skid, allowing for effortless integration.