TRM Filter, located in Ljubljana, Slovenia, is specialised in the development and manufacture of air filtration systems. The company was founded in 1982, starting out as a producer of filter elements, and had established itself in the market within a decade. The firm uses cutting-edge technologies as well as excellent materials to realise individual solutions – with the objective of fulfilling virtually every customer requirement regardless of its complexity.

Addressing high safety standards

The company also meets these requirements with one of its latest projects: TRM Filter was taken on board when a renowned client with international operations in the pharmaceutical sector was in need of a new granulation plant. The complete dust collection system which was ordered from the Slovenian experts had to satisfy very high safety standards, as demanded by the end customer. In this case, simply complying with legal regulations wasn’t enough – the pharmaceutical company’s own specification was far stricter. “Our customer in the pharmaceutical industry is aware of the dangers – especially the explosion risks – and therefore insists on the highest possible level of safety when it comes to dust collection systems”, explains Peter Tomšic, CEO of TRM Filter, who emphasises the importance of collaborating with explosion protection design professionals. Particularly in production environments where solvents are used, hybrid mixtures or flammable vapours have a high hazard potential that needs to be contained by means of adequate safety measures. A comprehensive explosion protection concept was developed for this purpose. TRM Filter enlisted the support of trusted partners with a history of successful cooperation.

The right product combination

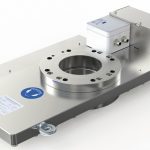

TRM provided the robust, explosion-proof ECO filter as part of a consistent and safe system for the end customer. This filter convinces with its ability to withstand explosion pressure due to dusts and hybrid mixtures up to a Kst value of 400 bar m/s. It also has a long service life before the filter needs to be changed. Its compact size with integrated secondary filters is another advantage, as are the low maintenance costs, especially when compared to explosion suppression dust collectors. The ECO filter is moreover ideal for difficult operating conditions such as high temperatures in the airflow. Tomšic eventually approached the experts at Rico Sicherheitstechnik, since the complete installation needed to be realised with explosion protection. Rico supplied two of its new RSV explosion isolation slide valves plus Ventex valves – which are implemented at the inlet of the fluid bed – to enable comprehensive constructional explosion protection. “These explosion isolation slide valves are the fastest in the market; they’re perfect for applications where the pipelines connect plant components. In case of an emergency, the pressure – or rather flame – sensor detects the explosion. The sensor activates a gas generator, leading to a pressure-induced instant shut-down of the slide valve”, explains Tomšic. Furthermore, the slide valves are made from stainless steel, so that corrosion risks are eliminated. They are especially suited for the pharmaceutical industry because all fittings are in accordance with the high hygienic requirements which apply there in production processes and cleaning cycles. The explosion protection slide valves are certified in accordance with the IP 65 protection class and are therefore resistant to influences such as dust or water. The generally reduced maintenance due to the low tare weight of the slide valve is likewise an advantage, and installation and handling are significantly easier.

The final concept for the plant was implemented by IEP Technologies of Ratingen, Germany. All essential steps were taken to meet the customer’s specification – resulting in an optimally protected plant for the pharmaceutical company. The detection and control systems provided by IEP connect the various solutions together efficiently. “The cooperation with Rico and IEP was necessary to provide a concept encompassing everything the end customer was looking for”, Tomšic comments, adding that employees, equipment, production processes and the environment needed to be properly protected and downtime reduced to a minimum.

TRM Filter and Rico Sicherheitstechnik have collaborated with one another for many years now. The two companies were in daily contact throughout the project, to ensure the best possible results for the customer. The technical requirements are always determined by the application. Tomšic stresses that the RSV explosion protection slide valve was the perfect solution for this latest project in view of the very complex production process involved.

www.cpp-net.com

Online search: cpp0118rico