Protection of the environment and resources are central goals in daily industrial use today. Waste avoidance and resource protection should be considered as central topics and kept in focus. Even the UN recently confirmed this with its Sustainable Development Goals (SDGs). The 17 ecological, social and economic sustainability goals formulated here include improved products, energy savings, optimised processes and the use of innovative materials.

Some of the individual goals listed here are not new. The efforts of the filter industry have long been reflected in the use of harmless filter materials and a corresponding material substitution. For ecological reasons, phenolic resins in filter cartridges, for example, have been replaced by alternative filter materials in recent years.

The positive filter properties of the phenolic resin, such as the high temperature and pressure resistance as well as the resistance to aggressive chemicals, can also be offered by other plastics that are more environmentally friendly to produce, such as polyamides (PA).

Environmentally friendly materials

Polyamide filter cartridges can reflect the advantages of the former phenolic resin cartridges in terms of thermal and chemical resistance. The filter matrix, i.e. the multi-dimensional internal structure of a PA filter cartridge, is completely different from that of a phenolic resin cartridge. In comparison, polyamide filter cartridges offer a more open pore structure and technical reproducibility, which is advantageous. The open pore structure ensures the dirt holding capacity inside the filter matrix.

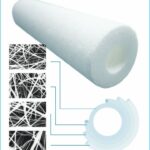

Based on the raw material nylon, the filter system manufacturer Wolftechnik developed the WFNMB depth filter cartridge as an alternative to the phenolic resin cartridge. The WFNMB is built up with a step-like configuration of decreasing pore-structure from the outside to the inside, a so-called deep structure. And it contains a nylon core support. This ensures the stability of the WFNMB in very high temperatures as well as in mediums with a high viscosity. The special chemical resistance of nylon allows its use for solvents, paints and varnishes at temperatures of up to 120 °C.

The special structure of the depth filter cartridge results in a long service life, high dirt-retention capacity and high throughput at low differential pressures. The very stable filter matrix of the WFNMB depth filter cartridge is manufactured using the melt-blow process. The raw material is melted in the extruder and discharged through a nozzle with pressure and hot air. This creates a fine-pored microfiber fleece.

Polyester replaces polyamide

In principle, all substances belonging to thermoplastics could be processed accordingly to form depth filter elements. Because sustainability in terms of resources is playing an increasingly important role, this insight was incorporated into the development of high-quality filter elements. Compared to polyamide, polyester proved to be more sustainable and better suited to processing and filtration. For this reason, Wolftechnik now uses PBT and PET instead of polyamide as an alternative to phenolic resin. Polybutylene terephthalate (PBT) and polyethylene terephthalate (PET) are thermoplastics from the polyester family.

The CPH depth filter cartridge consists of 100 % polyester fibers and has all the

advantages of the nylon depth filter cartridge, such as high thermal resistance (up to 120 °C) and very good chemical resistance to solvents. The depth filter cartridge is equipped with a fixed filter matrix and guarantees repeatable filtercharacteristics for high-quality applications. CPH depth filter cartridges are also available with code 3, code 8 and code 7 polyester adapters and end caps. High throughput and a long service life are further properties of the depth filter cartridge. Typical areas of application are the filtration of hot water 80 °C, varnishes, paints and inks, magnet-dispersion agents, fine chemicals, cosmetics as well as food and beverages.

Sustainability with recycled content

Protection of the environment and resources includes ecological and energy-efficient production processes and waste avoidance. In order to implement the 17 Sustainable Development Goals (SDGs) of the United Nations in the medium term, Wolftechnik has gone one step further and launched a polypropylene depth filter cartridge with

20 % recycled content for industrial solid-liquid filtration in autumn 2022. When developing the WFMBR melt-blow filter cartridge, the focus was not only on ecological aspects but also on customer benefits and user-friendliness. The recycled content does not have a negative effect on the properties (quality, filter performance) of the filter cartridge. It has all the important EU certificates, such as the FDA CRF21 certificate, food declaration of conformity, REACH declaration of conformity and RoHS declaration of conformity.

The WFMBR melt-blow filter cartridge marks the beginning of a development towards maximum resource and environmental protection in the field of filter elements. In principle, for example, recycled nylon would have the same advantages as recycled polyester or polypropylene (PP). PP, a thermoplastic produced by chain polymerisation of propene, was selected because it currently represents the product material with the largest quantitative share in the production of filter elements. Because one of the challenges of the innovative development was to keep the usable amount of recyclate in stock for a stable production process. Theoretically, up to 50 % recycled content would be technically possible. But the amount of material is still missing. Current research is therefore dealing intensively with this topic, also in order to further reduce the costs of the recycling process.

Depth structure with four stages

The new WFMBR melt-blow cartridge replaced the well-known WFMB melt-blow cartridge at the end of 2022. The filter cartridge with recycled content is made entirely of PP and is free of binders and adhesives. It is produced in the melt-blow process, whereby with four different spray nozzles finer and coarser endless fibers can be processed into a multi-layer structure. Inside the depth filter structure are the fine layers, on the outside the coarse ones. This four-layer gradation allows the coarse particles to be retained in the outer layers and the finer particles to be retained on the inner layers. This enables the excellent product properties of the WFMBR.

The depth filter cartridge is optionally available with ends open on both sides (DOE) or with the common adapter configurations (Code 0, Code 5, Code 7, Code B) and with nominal filtration rations from 0.5 to

100 μm. In addition to the standard version (Ø 63 mm), it is also available in a big version with Ø 110 mm in lengths from 47/8“ to 40“.

Suitable for temperatures up to 80 °C, the depth filter cartridge offers a wide range of applications. For example it can be used as a fine filter for cooling circuits or for vegetable oil, as pre-filters for RO+DI water treatment systems, at the acid and lye filtration in the electronics industry, for photo chemicals and light viscose fluids.

Wolftechnik Filtersysteme GmbH & Co. KG, Weil der Stadt

(1) The PP depth filter cartridge for separating solids from liquids from Wolftechnik has a recycled content of 20 %

Picture: Wolf Martin Wagner

(2) The WFMBR melt-blow cartridge is manufactured using the melt blow process, whereby with four different spray nozzles finer and coarser endless fibers can be processed into a multi-layer structure

Picture: Wolftechnik

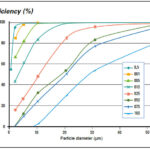

(3) Despite the recycled content, the efficiency of the new polypropylene depth filter cartridge remains identical to the previous product

Picture: Wolftechnik

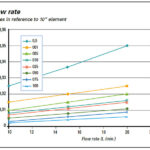

(4) The flowrate is identicall as well

Picture: Wolftechnik

(5) Author:

Peter Krause

Managing Director,

Wolftechnik