The Flocformer’s ability to remove water from sewage sludge up to 30 % more efficiently has repeatedly been proven in practice. Aquen aqua-engineering has now also come up with a method for improving the efficiency of landfill leachate treatment based on its successful flocculation unit. The pilot plant for this process in Osterode has undergone extensive testing since 2007. The significant potential reduction in operating costs has meanwhile been confirmed in normal operation.

Author Dr. Christian Schröder Managing Director, Aquen aqua-engineering

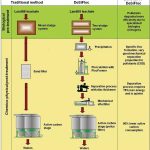

Treating landfill leachate presents several daunting challenges for the process technology. After all, landfill leachate contains a cocktail of various pollutants. In addition to biodegradable nitrogen compounds, these also include a large number of other organic and inorganic pollutant groups that are partially or completely non-biodegradable. These substances have to be removed from the landfill leachate by means of cost-intensive chemico-physical treatment. The Desifloc concept for landfill leachate flocculation includes an internationally patented process that separates the pollutants much more efficiently than is possible using traditional methods. The main part of this process comes into play after biological pre-treatment. All non-biodegradable or residual pollutants are targeted in the Flocformer process and can then be filtered out of the waste water flow.

The Flocformer is a special flocculation reactor at the heart of the plant. By choosing the Flocformer, the landfill leachate treatment process can be made more consistent in terms of processing and costs compared to conventional alternatives. Throughout the entire system the focus is on removing all pollutants – apart from biodegradable nitrogen compounds – efficiently from the waste water.

Desifloc makes a good impression

The leachate at the Osterode district landfill in Hattorf on the edge of Germany’s Harz mountains has traditionally been purified biologically and then post-treated chemico-physically (coagulation, separation, active carbon adsorption). The pollutant with the high-est concentration at the inlet of the chemico-physical treatment stage is the residual or non-biodegradable COD. Depending on the leachate composition, this can be anything from 30 to 70 % of the original COD. The relatively high contamination level of the water in Hattorf meant malfunctions were a common occurrence, both in the biological part of the leachate treatment plant and in the downstream filtration stage. The only way to avoid these problems was to reduce the treatable volume flow rate significantly – at the price of very high outlay for leachate disposal. A method needed to be found for conditioning the landfill leachate cost-effectively using a combination of chemico-physical treatment and an active carbon stage, so that it was always within the limit values for discharge effluents.

The landfill leachate treatment plant in Hattorf was completely refurbished seven years ago. In addition to upgrading the biological process, a novel method was introduced for precipitating/flocculating the leachate. In a configuration with a simple disc thickener as sepa-ration apparatus for reducing the COD, the Flocformer flocculation reactor has proved to be outstandingly efficient and reliable. The Flocformer’s job is to form a specific floc structure during the flocculation process. The majority of pollutants can then be bound in the flocs to facilitate mechanical separation.

The Flocformer has two characteristic effects that cut the costs of operation:

- The actual COD separation process can be achieved using gravity filtration, which is technically straightforward. The COD no longer needs to be eliminated in the upstream biological process.

- The Flocformer greatly improves the COD separation performance and reduces the load on the active carbon stage by almost 90 %.

A belt filter with a very fine mesh downstream of the disc thickener enables any residual suspended matter to be removed from the landfill leachate. The mechanical filtration of the pollutants in the leachate is followed by active carbon adsorption. Provided the flocculation-initiated separation process is fully adapted and efficient, the active carbon stage merely acts as a police filter for the COD parameter.

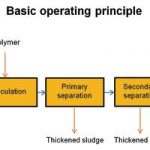

Operating principle and components

The systems installed in the plant agglomerate and flocculate the substances in the process water and then separate these flocculated substances from the liquid. The biologically pre-treated landfill leachate is first of all electrically destabilised by adding ferric chloride. This de-stabilisation causes organic substances to precipitate, so that the COD and AOX are reduced and micro flocs form. The ferric chloride results in a lower pH, which can be used as a controlled variable. The micro flocs formed in this way are converted into stable macro flocs with the help of flocculating aids (synthetic polymers). Two phases develop – the floc structure containing solids and pollutants and the relatively clear residual water. The downstream separation process is much more efficient thanks to the targeted formation of the floc structure. The primary COD separation step is mechanical: the stable floc structures are screened. Agglomerated solid is then removed from the clear phase again in a secondary separation process involv-ing very fine post-screening. This filter mainly serves to protect the active carbon adsorption stage located downstream. Following mechanical separation, the treated mixture of landfill leachate and process waste water is neutralised to a pH of around 6.5 in a mechanical-biological treatment process by adding 50 % sodium hydroxide solution.

Treatment costs compared

The table shows the specific treatment costs for the two processes described here (before/after). The original operating principle of the landfill leachate treatment plant with a reduced volume flow resulted in imputed costs of approximately €4/m3 in the active carbon stage. The real value was probably higher, however, owing to the blockage of the carbon. When the plant was extended with the adapted biological process and the chemico-physical Desifloc stage, the entire inflow to the landfill leachate treatment plant could be conditioned far more eco-nomically. The annual saving compared to just active carbon adsorption is considerable. Desifloc is scalable: each module has a basic throughput of 6 m3/h for landfill leachate. If necessary, several modules can also be operated in parallel without any problems. The investment costs for the plant are normally recovered within a matter of one or two years.

cpp-net.com/0214439

Share: