Tanks are filled with different products such as gasoline, gas oil, VGO, heating or heavy oil as well as various chemicals. The pumps used must therefore have particularly good suction properties in order to ensure that the tanks, tankers, ships or tank waggons are completely emptied – same for the pipelines. A point where the VPS pumps show their strengths.

With only two seals

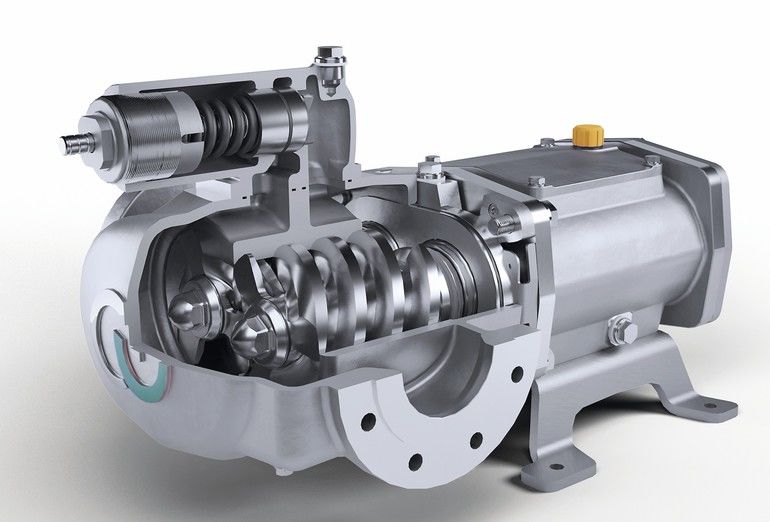

In the case of single-flow pumps, the pump chamber is sealed off from the atmosphere using only two seals, which are arranged either on the suction or pressure side. The pump housing structure is kept very simple and access to the conveying elements and mechanical seals is quick and easy in just four steps. This makes the pump very easy to maintain. Single-flow VPS screw pumps are rotating displacement pumps that work with two intermeshing, contact-free delivery screws that are designed with different pitches depending on the application. Rotation creates chambers that move from the suction side to the pressure side and thus convey the medium. Due to the reversal of the direction of rotation, reversible operation, i.e. pressure and suction, is possible without changing the pump.

The axial conveyance enables a stable performance curve in a very wide speed range – up to a factor of 10 wider than with alternative positive displacement pump technologies. With different housing materials and feed screw pitches, a wide range of application areas are possible for the VPS series: from very thin media such as ethanol to barely flowing media such as heavy oil or bitumen.

Areas of application and variants

The VPS series conveys non-lubricating media or media loaded with solids, low to high viscosity media as well as liquid-gas mixtures with almost no pulsation. The medium temperature can be up to 210 °C.

The VPS series is available as Atex (indoor and outdoor) and TA-Luft-compliant version. The available product variants are structured according to pressure range and volume flow and are each available in stainless steel or cast steel. The basic version of the VPS series covers areas of application up to 500 m3/h and up to 25 bar. It is supplemented by the inline version VPSI. The VPS Power Pack connects two pumps in series and enables up to 50 bar at 150 m3/h. The VPS Flow Pack connects two pumps in parallel and enables 1000 m3/h and up to 16 bar. It is interesting for customers who have strongly changing flow rates in operation, who do not want large motors and converters or who simply want to be on the safe side.

Fristam Pumpen Schaumburg GmbH, Stadthagen, Germany