Firmen im Artikel

Seals are mostly made of elastomers, commonly known as rubber. In its pure form, rubber cannot process signals. In many cases, however, signal processing would definitely be an advantage since seals are often installed in central locations in machines and are vital for their functioning. For this reason, researchers at Freudenberg Sealing Technologies are investigating materials that enable seals to be used as sensors or even actuators – for example, with the help of diaphragms that perform certain actions. At the same time, it is important to keep the research on track and not lose sight of the seal’s original task.

Special fillers

One solution involves integrating a sensor or a microchip into the seal. This makes it possible to equip a seal with intelligence but has its limits because integrated components are foreign bodies that cannot be allowed to impair the seal’s function. As a result, the developers at Freudenberg Sealing Technologies have turned their attention to approaches where the intelligence comes from the material itself. For instance, special fillers incorporated in the elastomer help impart additional properties like magnetism to the seal, which can even act as a permanent magnet. Another option is to integrate conductive filler material into the elastomer mixture. In either case, it is crucial for the filler to combine its magnetic or electrical characteristics with high elasticity, good setting behaviour, a high tolerance of temperature fluctuations and good media resistance, so that it has no negative impacts on the actual sealing function.

Conductive rod seal

The advantage of additional functions can quickly outweigh the extra manufacturing costs, such as when a seal recognises its own wear, if the entire value chain is considered. A rod seal comprised of a conductive elastomer and an insulating outer layer is one good example here. The outer layer is the sealing lip in the seal. When an electrical circuit connects the rod to the housing wall, current can become a measurable variable. As the rod seal moves back and forth, the sealing lip abrades. If the conductive base material appears through the surface, the electrical circuit between the rod and the housing closes – a condition that could be indicated by an LED. A relatively simple solution is all it takes to reduce operating costs. The seal’s entire lifespan can be utilised because it is not replaced prematurely. Conversely, there are no costs due to leakage, which may occur if a seal is removed too late. Automated maintenance support is moreover an important requirement in networked facilities.

Dynamic sealing elements

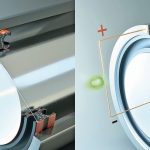

Smart seals allow functions far beyond mere self-monitoring to be incorporated. For example, Freudenberg Sealing Technologies are currently researching a variety of dynamic sealing elements such as diaphragms, which serve as movement or force sensors, as well as intelligent U-rings, which can indicate the absolute position of pistons and cylinders in construction equipment. This is possible using so-called dielectric elastomers. The approach involves constructing a diaphragm like a sandwich. The two outer layers consist of an electrically conductive elastomer while the inner layer is made from an insulating elastomer. In physical terms, this represents a capacitor. When the diaphragm moves, both the surface and the distance between the capacitor plates change, resulting in a change in capacity. The force acting on a diaphragm can be measured in this way.

The effect also works in reverse. If a voltage is actively applied to dielectric elastomers, the elastomer is pressed together. If not simply a single sandwich is used but an entire stack consisting of several layers, this kind of elastomer structure could also act as a valve. When the electric current is applied, the stack as a whole is pressed together and the valve opens. When the current is removed again, the elastomer layers return to a relaxed state. The valve can be steplessly adjusted. Energy consumption is low because the electric current is only needed to actually execute the function. Even if this type of sealing element is still a long way from series production, it clearly demonstrates the technology’s potential.

Wide range of applications

A wide range of potential applications exists for smart seals. One advantage is that they can be used in any conceivable medium because their base material is geared to the particular application. However, researchers are not just focusing on modified base materials but also on intelligent coating systems. For example, thermochromatic coatings for temperature measurements can be employed at precisely the point where a seal is thermally stressed, say, in an engine’s interior. This is particularly beneficial in places where no conventional sensor could ever be installed. The design of the seal and the selection of its material can be even better adapted to specific applications in this way.

Online search: cpp0318freudenberg