Preventing problems with the mechanical seals that are used on pumps and reactors for handling polymer dispersions is a major engineering challenge. Essentially, the problem is that polymer dispersions are not thermodynamically stable and they tend to coagulate. Polymer particles form compact agglomerations which can quickly bring the process to a halt. EagleBurgmann has developed a sealing strategy specifically for this difficult application.

The author: Ellen Klier Group Marketing, EagleBurgmann Germany

Latex is a dispersion of tiny polymer particles in water. The milky fluid contains about 50 % water by weight. The diameter of the latex particles is in the order of a few ten-thousandths of a millimetre. The polymer core is surrounded by a polar shell that interacts with water, stabilising the dispersion. Synthetic polymer dispersions are produced by polymerisation of monomers in aqueous solution in a reactor. Mechanical seals are used on the pumps at all stages of the dispersion production process, including raw material infeed, polymerisation, dispersion processing and finished product tank storage. The pumps run continuously or intermittently at different stages of the process.

The engineering challenge is to design seals for the pumps that are used to handle dispersions (latex). The problems are particularly acute in process steps where the dispersion contains latex laden with residual monomers, for example during dispersion processing. All the stages in the latex production process take place at low temperature and pressure. One major reason why more extreme production conditions are avoided is the fact that polymer dispersions are not thermodynamically stable and tend to coagulate, making the medium difficult to pump. Adhesiveness, which is desirable in the finished product, can cause leakage or total failure of the seals. Latex adheres to the warmest surface (the seal faces) and diffuses after only a few hours between the sliding faces. The seals then open against the force of the buffer pressure. Ensuring that the shaft seals do not leak is particularly important in this difficult process step.

Double mechanical seals are pressurised with buffer fluid. The buffer pressure acting in the direction of the product (latex) decreases in the seal gap. As a result, latex and the buffer medium intermix on the product side. Friction heat in the seal gap causes agglomeration of the polymer particles. When this happens, the seal gap opens and the seal may be destroyed. The buffer fluid can then leak out or latex can penetrate into the buffer chamber, causing the seal to fail. To avoid this scenario, the EagleBurgmann engineering team had to come up with a seal design that prevents contact between the seal and the product. Since the pumps run continuously or intermittently depending on the process stage, a different sealing solution was needed for each of the two operating modes.

Customised sealing solutions

For intermittent operation, the supplier chose an MG1/65-G9 single seal. To prevent contact with the latex, EagleBurgmann added a throttle, so that the product-side seal can be flushed with clean water. Water is needed in the production process in any case, so using it in limited quantities does not cause problems. To prevent flush water from totally flooding the pump when it is shut down and ensure that residual latex in the pump does not penetrate into the mechanical seal, an STD1 shut-down seal was installed in the cartridge seal. The seal is automatically pressurised with compressed air following a time delay after shutting down the pump. The bellows seal presses against the shaft, separating the medium from the me-chanical seal. Flushing can remain activated throughout this step. Nothing flows into the process during this time. Before the pump is started up again, the compressed air is automatically shut off and the bellows retracts from the shaft. The pump then starts running. In trouble-free operation with external flushing, the seal service life meanwhile extends well beyond a year.

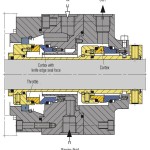

For pumps that handle latex containing monomers, EagleBurgmann engineers have developed an enhanced seal version that complies with clean air regulations (TA-Luft): a double Cartex cartridge seal with a throttle for controlled flushing in the direction of the impeller. A knife edge is placed on the product-side seal face to provide an added margin of safety, ensuring that the mechanical seal does not fail due to insufficient flushing. No shut-down seal is needed because the pump runs continuously.

The development and optimisation activities for this project included the rubber bellows single seal for intermittent operation and the double cartridge seal with a flush throttle ring on the product side as well as a knife-edge face. These mechanical seals also created an opportunity to optimise the pumps and significantly increase their service life. Due to shear forces, lumps can form behind the impeller, blocking it and causing the motor to shut down as a result of overload. The back vanes on the impeller have now been removed, reducing shear forces and preventing agglomeration. These modifications – along with other improvements to extend the total service life of the pumps – were only possible in conjunction with the modified seal system.

The operating mode of the seal is likewise unusual, as there is no pressurised buffer system. An external water supply is used for the buffer and flush functions. A central water supply guarantees high availability. An EagleBurgmann FLC flow controller ensures a constant, defined flush flow which is not dependent on pressure.

Efficiency and productivity gains

Eight seals are now running continuously and one is operating in intermittent mode. The customer, PolymerLatex GmbH – a joint venture formed in 1996 by Bayer, Degussa and Röhm – is completely satisfied with the results. “The level of collaboration between our company and the EagleBurgmann Service Center has been excellent since day one. Through an extremely constructive and professional joint effort, we very quickly developed initial prototypes that provide a solution to what appeared to be an intractable problem”, says PolymerLatex Engineering Manager Christian Scholten. Subsequent development work has been equally satisfactory. The service life in the most problematic process stage has been increased dramatically from just a few hours of operation to as much as 1 1/2 years.

Based on the good results so far, PolymerLatex is planning to deploy additional modified Cartex seals at the plant. The service life of the seals currently installed is much longer (up to 3 years in some cases) compared to the seals that were used previously. Even when pumps are removed and cleaned, the seals are mostly reinstalled without repair.

Online-Info: www.cpp-net.com/2111438

Share: