At a recent press conference upfront of Achema, the VDMA Process Technology Group presented figures to show the economic trends in its various member industries. The general consensus was that the recession is now over. Following a successful 2011 – when productivity increased 14 % in the first three quarters – German manufacturers of process technology expect to stay on their growth trajectory throughout 2012.

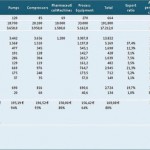

Without the construction of large-scale chemical plants, German process technology manufacturers produced machinery and apparatus with a combined value of more than EUR 17 billion in the first three quarters of 2011. “This represents an increase of 14 % compared to the first three quarters of 2010,” said Dr. York Fusch, Chairman of the VDMA Process Technology Group and CEO, Körting Hannover AG, Hanover. During the same period, exports grew by 14 % to EUR 13.8 billion. The export share rose from 72 % in 2010 to 80 % in 2011.

The region of the 27 EU countries still remains the biggest sales market for process technology machinery, apparatus and plants with a 37 % share of overall exports. “Although we are currently hearing increasing reports about projects being delayed due to uncertainties over the sovereign debt crisis, exports to the 27 EU countries have recently risen again – by slightly more than 11 %,” said Dr. Fusch.

Asia (without the Middle East) is the second most important sales region, with an export share of 21 %. Exports to Asia have increased year-on-year by 26 % to EUR 2.9 billion. The biggest market within Asia is China, closely followed by India and Korea. “In terms of process technology machinery and apparatus alone, Korea is the most dynamic market in Asia,” Fusch added.

Energy efficiency and sustainability

In essence, the new products and innovations at Achema address the following core topics: improving quality of life, resource efficiency, protection of the environment and, last but not least, cost effectiveness and profitability.

Reducing maintenance and energy costs by improving the cleanability and accessibility of components, increasing cost-effectiveness and profitability with optimised efficiency, more compact designs, quicker changeover times, space-saving machinery, more reliable processes and greater process safety for people and products – these are all important topics which are being addressed by the German process technology manufacturing industry.

Accordingly, it is a logical step for many companies to get involved with Blue Competence, VDMA’s sustainability initiative. Sustainable production methods and products are not always easy to spot at first glance, which is why the Blue Competence label has been introduced as a way for participating enterprises to emphasise their strong commitment to sustainability.

“The subject of sustainable management has also arrived in the German valve industry,” confirmed Dr. Achim Trasser, Member of the Executive Board of both Sempell AG, Korschenbroich, and the VDMA Valve Manufacturers Association. German valve manufacturers place great value on high product quality, first-rate service, a long service life, efficient products and careful use of resources. Proximity to the customer is a central element of their success.

Dr. Sönke Brodersen of pump manufacturer KSB stressed that the pumps sector is ‘under a lot of pressure’ to increase energy efficiency: following the European Eco-Design Directive EuP/ErP for heating recirculation pumps and the just-published draft for water pumps, he considers it to be only a matter of time before industrial pumps, too, come under the scrutiny of the EU authorities. Brodersen, Chairman of the VDMA Pumps + Systems Group, also sees this as an opportunity, however: “As a result, our ability to innovate is also helping us to establish a competitive advantage internationally.”

This view is shared by Alexander W. Peters, Managing Partner of the Neumann & Esser Group and Chairman of the VDMA Compressors, Compressed Air and Vacuum Technology Group.

The energy turnaround will open up completely new markets, particularly for suppliers of compressors. The capture and storage of CO2 (CCS) and the feed-in of biogas from organic waste into existing natural gas networks are just two examples. New applications will also be created in healthcare and environmental protection.

Hall 5.1, Booth B76

cpp-net.com/0212400

China remains the principal export market

Industrial valves

Sales by industrial valve manufacturers organised within the VDMA increased year-on-year by a nominal 6 % in 2011. All in all, domestic sales developed along the same lines as exports throughout 2011. In Germany, the figure rose by a nominal 7 % while international sales were 6 % higher than in the previous twelve months.

Last year, German industrial valve manufacturers generated an export volume of EUR 3 billion. China, the US and Russia maintained their position as the top three sales markets for industrial valves made in Germany. With valve shipments totalling EUR 402 million (equivalent to an 18 % increase over 2010), China remains the principal export market.

For 2012, the German Valve Manufacturers Association is predicting a nominal 5 % increase in overall industrial valve sales. Positive impetus is mainly expected from oil and gas extraction and the petrochemicals sector.

Double-figure export growth in 2011

Compressors, compressed air and vacuum technology

In the first three quarters of 2011 alone, 16.6 % more compressors, compressed air and vacuum technology were produced than in 2010. The VDMA Compressors, Compressed Air and Vacuum Technology Group is predicting a similarly positive trend for the fourth quarter and remains confident for the whole of the current year. A slight increase in sales is therefore also realistic for 2012. Following a real 10 % rise in 2010, demand was up a further 7 % in 2011. A double-figure increase – a massive 22 % – was recorded in sales.

In 2011, Germany exported compressors, compressed air and vac-uum technology worth EUR 4.9 billion, equivalent to an increase of 10.2 %. As in previous years, the key customer countries for German exporters were located in Europe. The share decreased from around 46 % in 2008 to only 40 % in 2009, however, before rising once again to 42 % last year. The Rest of Europe, (North and West) Africa, (Central, South and East) Asia and North America regions showed double-figure growth rates in 2011. By contrast, a double-figure decline was reported in the Near and Middle East as well as in South America. As in previous years, China is the principal export market with nearly 15 % – ahead of countries such as the US and France.

Still expanding

Pumps + systems

In the first three quarters of 2011 alone, 12. 9 % more pumps were produced than in 2010. The VDMA Pumps + Systems Group is predicting a similarly positive trend for the fourth quarter and remains confident for the whole of the current year. A 2 % increase in sales is therefore also realistic for 2012.

The VDMA’s incoming order statistics for liquid pumps reflect the economic situation of German pump manufacturers: following a real 20 % rise in 2010, demand was up a further 10 % in 2011. Capacity utilisation, which is a good indicator of the order intake level, was ’moderate’ at 84.2 % in January 2012. Generated turnover was likewise positive at 10 %.

German exports are undeniably impressive: in 2011, Germany supplied 14 % more liquid pumps abroad than in 2010, equivalent to an export volume of nearly EUR 4.7 billion. The figures for oscillating and rotary displacement pumps were particularly awe-inspiring, growing by 18.9 % and 18.6 % respectively. Centrifugal pumps, which accounted for the biggest piece of the cake with more than a third of all pumps exported, were up 7.7 %. The 27 EU countries declined in importance – albeit only slightly: during 2008, 49 % of German pump exports were still destined for these countries, whereas since 2009 this share has fallen to a maximum of 46 %. In 2011, exports to most regions showed double-figure growth rates. The only decrease was in exports to North Africa. China, the US, France and the Czech Republic were the principal export markets in 2011.

Share: