Firmen im Artikel

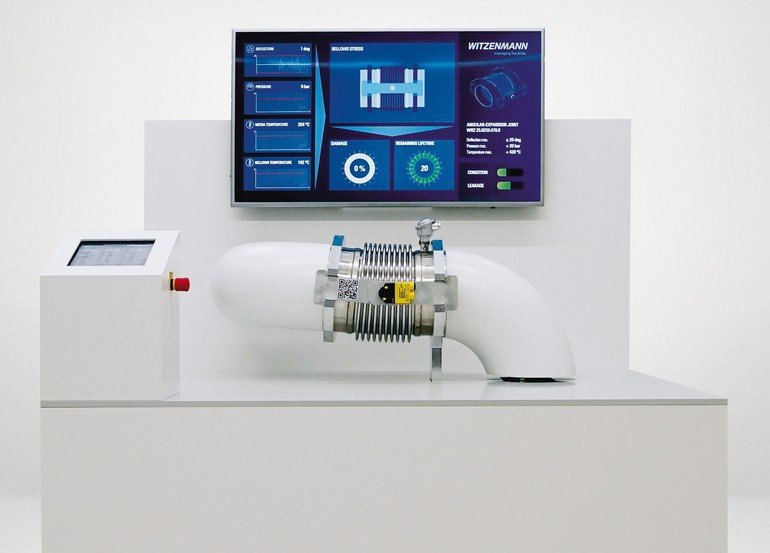

Expansion joints are among the most important safety elements in the pipeline network. The Witzenmann IoT expansion joint study allows a continuous evaluation of the operating condition in real time due to intelligently linked sensors. An FEM model of the expansion joint that provides information on and visualises the current load situation of the bellows is generated continuously in real time via a dashboard. At the same time, the remaining service life of the component is continuously calculated from the actual operating data. The degree of damage can therefore be estimated precisely, and any regular replacement or inspection intervals can be planned. The expansion joint records all relevant data, even effects that are not planned for the system, such as, e. g., pressure shocks or unplanned temperature courses. When a component is replaced, the manufacturer can therefore precisely evaluate its load for the plant operator. The added value results from this cause analysis, which makes it possible to design subsequent components for the plant requirements. The knowledge and availability of detailed operating data are reflected in a higher operating efficiency and longer service life of the entire plant here as well.

Online search: cpp0318witzenmann

Hall 4, Booth B22