Firmen im Artikel

Zetrix, the triple offset butterfly valve from ARI, has already proved to be extremely versatile, durable and highly reliable in practice, even in harsh industrial environments. This valve has now undergone extensive testing in two different temperature classes at Amtec’s accredited laboratory in accordance with EN ISO 15848. The objective was to verify the equivalence of the sealing system with the bellows seal recommended by TA Luft.

Both TA Luft [1] and DIN EN ISO 15848-1 [2, 3] aim to mitigate or reduce fugitive emissions which are harmful to the environment and human health. TA Luft is a comprehensive German regulation which specifies binding technical requirements for classified installations in accordance with the 4th Federal Immission Control Act. EN ISO 15848-1 is an international standard which provides users with evaluation criteria for classifying valves (isolation and control devices), to enable different designs or brands to be compared. Although compliance with the requirements of TA Luft is considered to be proof of a sealing system’s quality – not just in Germany but in many other countries too –, EN ISO 15848-1 is playing an increasingly important role in the chemical, petrochemical and process industries.

Test standards

Section 5.2.6.4 “Shut-off devices” of TA Luft refers to a metal bellows with a downstream packing gland or sealing systems of similar effect as the latest technology for sealing shaft bushings for isolation and control devices. The more expensive bellows option would often be the better choice for technical reasons; however, the proven packing gland is still regularly chosen for stem seals. Sealing systems “of similar effect” are defined as systems which are capable of maintaining the temperature-specific leakage rates during the proof procedure pursuant to VDI Guideline VDI 2440 [4].

Proof pursuant to VDI 3.1.3.3 must be furnished for a test sample which is representative of the sealing system at temperatures, pressures and stem or shaft movements corresponding to the actual operational conditions. The equivalence of a sealing system is deemed to be demonstrated if a leakage rate of 10-4 mbar·l/(s·m) or 10-2 mbar·l/(s·m) is maintained at a temperature of 250 or ≥250 °C respectively.

EN ISO 15848-1 specifies the test conditions and requirements in much greater detail in that the valves are generally grouped according to tightness, endurance and temperature classes. The test specifications take account of the significant requirements for isolation and control valves by means of different mechanical cycles and lift movements. In contrast to TA Luft a tightness criterion is specified for the static body seal (⩽50 ppmv). This allows users to evaluate the expected fugitive emissions from the valve as a whole.

The valve qualification or classification must be demonstrated by means of a type test; provided the design is identical, the results can also be transferred to other types with a stem or shaft diameter between 50 and 200 % of the test sample.

If we consider the leakage rates of stem and shaft seals – EN ISO 15848-1 [2, 3] and TA Luft compared –, we realise that the leakage rate which is achieved under the test conditions is also decisive in the standard. A total of three tightness classes are specified independently of the temperature: class A implies equivalence for the sealing systems of rotary valves with a bellows, for example. In the 2015 edition, which came into force in November 2015, the leakage rate for class A has been increased, bringing it closer to TA Luft [1]. It can be seen from the table that tightness class A always satisfies the TA Luft criterion; in the case of classes B and C the temperature-dependent criterion must be verified.

Qualification and classification of Zetrix

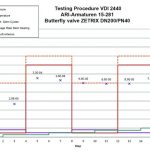

A test sample of the butterfly valve (rotary valve with 90° travel), fitted with a high-grade graphite packing without a spring for sealing the shaft bushing and a serrated seal as a static seal for the bottom flange, was tested and certified according to DIN EN ISO 15848-1:2006-04 in two different temperature classes at Amtec’s accredited laboratory.

The results for temperature class 1 (maximum RT 200 °C) [5] were:

ISO FE AH – CO3 – SSA 0 – t(RT, 200 °C) – (40/35 bar) – ISO 15848-1 [3]

where FE – fugitive emissions, AH – tightness class A with test fluid = helium, CO3 – endurance class CO3 with 2500 mechanical cycles in four thermal cycles up to RT 200°C, SSA 0 – number of stem seal adjustments = 0, t(RT, 200 °C) – temperature class maximum RT 200 °C and (40/35 bar) – pressure rating at test temperatures.

The leakage rates measured during the test were always less than the 10-4mbar·l/(s·m) criterion; this is also confirmed by the class A tightness which was achieved. The sealing system can thus be deemed high-grade as defined by TA Luft under the test conditions described.

The results for temperature class 2 (maximum RT 400 °C) [6] were:

ISO FE BH – CO3 – SSA 0 – t(RT, 400 °C) – (40/23.6 bar) – ISO 15848-1 [3]

The tightness with helium as test fluid in this case is B and there are 2500 mechanical cycles to carry out in four thermal cycles (maximum RT 400 °C). Up until the end of the second thermal cycle and 500 mechanical cycles the leakage rates measured during the test were always in the region of the TA Luft 10-4mbar·l/(s·m) criterion at RT and 10-2 mbar·l/(s·m) for 400 °C. The sealing system can thus be deemed high-grade as defined by TA Luft under the test conditions described.

Positive result

The stem seal of the Zetrix triple offset butterfly valve is fully compliant with the TA Luft criterion in the temperature class up to 200 °C under the conditions described in DIN EN ISO 15848-1. In the temperature class up to 400 °C the criterion is fulfilled up to 500 mechanical cycles in two thermal cycles, in other words equivalence with a bellows seal is proven.

Since a specific classification is possible according to DIN EN ISO, a valve’s performance can be classified in terms of its ability to reduce and mitigate fugitive emissions, as demonstrated by this example. Different designs or operating parameters can thus be directly compared.

The manufacture and installation of the valve entails considerable challenges and requirements in order to ensure conformity with these two technical regulations. The stipulated leakage rates can only be achieved by observing narrow limits with regard to the stem surface finish and the gland hole and by utilising a high quality bearing with a precisely tensioned gland.

In-service examination

A Zetrix triple offset butterfly valve with a nominal diameter of 350 mm was subjected to an endurance test lasting approximately three months with synthetic thermal oil at the in-house test facility. The valve completed eleven thermal cycles and 10,000 mechanical cycles between RT or 100 and 350 °C at approximately 10 bar fluid pressure. Any leakage at the stem seal is drained off and collected by means of a lantern ring underneath the packing box flange. No leakage whatsoever occurred at any time during the test. The high quality of the stem seal described here was thus proven under realistic operating conditions – offering further confirmation of the results obtained in the laboratory.

Literature

[1] TA Luft, First General Administrative Regulation Pertaining to the Federal Immission Control Act (Technical Instructions on Air Quality Control – TA Luft) of 24 July 2002.

[2] DIN EN ISO 15848-1, Industrial valves – Measurement, test and qualification procedures for fugitive emissions – Part 1: Classification system and qualification procedures for type testing of valves (ISO 15848-1:2015); German version EN ISO 15848-1:2015.

[3] DIN EN ISO 15848-1, Industrial valves – Measurement, test and qualification procedures for fugitive emissions – Part 1: Classification system and qualification procedures for type testing of valves (ISO 15848-1:2006); German version EN ISO 15848-1:2006.

[4] VDI 2440, Emission control – Mineral oil refineries – November 2000.

[5] Amtec, Test Report-302 586 2/-, 2014.

[6] Amtec, Test Report-302 586 4/-, 2015.

www.cpp-net.com search: cpp0117ari

Michael Vullhorst

Laboratory Manager,ARI-Armaturen

Firmen im Artikel

Share: