Feige automatic drum fillers fill up to 120 steel bung-type drums with a volume of 216.5 l per hour. The same amount of empty drums must be available per hour – and the amount even multiplies with the number of installed drum fillers. Taking into account the dimensions and the weight of empty drums the handling mainly represents a logistic problem which can be solved with semi or fully automatic equipment.

Dipl.-Ing. Harald Niemann

Today, the distribution of liquid and pasty products is hardly feasible without the use of 200 l drums. Millions of steel or plastic drums are produced world-wide every year to be filled with pumpable products. In tough standardisation work drum manufacturers, filling companies and filling equipment manufacturers have agreed upon certain drum design features. The European standard EN 210, for example, describes the steel bung-type drum with a total volume of 216.5 l. This means of packaging meets all demands on safe transport and storage of even dangerous goods and food.

Up to 800 drums per hour are produced on highly-mechanised production lines, checked and loaded, afterwards supplied to the filling company. Given this enormous production output, drum manufacturing can only be “just in time”. A Feige drum filler, for example, positions, de-bungs, fills, re-bungs and seals up to 120 drums per hour, all fully automatically. Thus, the drum fil-ler continuously needs two drums every minute.

Temporary storage required

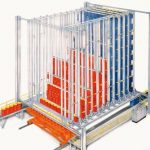

The drums will be directly be unloaded from the lorry onto a telescopic conveyor which moves the drums to a rol-ler conveyor. This roller conveyor can directly move the drums to the drum filler. In this case, drum supply and drum filling would be combined. A possible consequence, however, would be that only those drums could be filled that have just been unloaded. But in most cases such a direct dependency is not wanted, rather do the filling companies aim at a temporary storage with drum type classification. In general, there are two possibilities of drum storage: In case of sufficient space storage roller conveyors receive the drums according to the lorry unloading speed and supply them as required in cycled operation to the drum filler. For a restricted area, an empty drum silo which can take 900 to 3000 drums depending on the design, offers the required storage function. The integrated silo stacker stacks the 200 l drums in rows within the single cells. The stacker is also used for the removal from stock when the drums should be supplied to the filling equipment.

Heavy manual work

Empty drums weigh about 20 kg. Thus, manual drum handling requires sufficient physical strength and appropriate recreation of the personnel. Already at an early stage Feige has developed an automatic system for drum unloading aiming at humanising and rationalising the workflow. The unloading robot moves on chains into the lorry and stops short before reaching the drum rows to be unloaded. Vacuum gripper extend and contact the drum shells. Afterwards, the robot moves back to the base position and places one drum row after the other onto the roller conveyor which is located between the lorry and the robot’s base position. This system, however, is limited to only a few fields of application due to different lorry types and different loading and unloading modes.

Pallet loading

The CP3 and the CP9 pallet with the dimensions 1140 x 1140 mm has particularly been designed for charging pallets with drums. Three pallets with four drums each will reach a stacking height of about 3.1 m. This is too high to bring this stack into standard vehicles. Only low-floor vehicles with elevating roof which is closed while running enable the triple stacking height for road transport. A forklift truck will then unload the pallets after the lorry has arrived at the filling company. This helps to eliminate a good part of labour intensive and heavy work.

A reusable plastic pallet system is highly efficient for the transport and the storage of steel drums. This system consists of a stable deep drawing 4-way pallet with two light slip sheets. The contours of the pallet and the slip sheets provide for a positive locking between drums and pallet. In this way, 12 empty drums can safely be placed on a surface of 1200 x 1200 mm in the stack. As the slip sheets are not very thick, the pallets can be loaded onto a conventional lorry.

The fixation of the drums in the contours of the pallet system protects the drums from dents and prevents damage to the paint during transport. Apart from the positive aspect of increasing the quality, the empty drums are exactly aligned to the pallet contours which enables the use of automatic handling devices.

Four drums each that have been produced every 4.5 s can automatically be inserted into the plastic pallet system. Using a simple pallet hand truck, the lorry driver puts the stack with three layers and four drums each into the lorry and unloads the stack on site. The triple pallet stacks will then be stored on pallet conveyors according to drum classification. An automatic storage management system can be added. Thanks to exact drum positioning, an articulated robot is able to unstack the drums fully automatically and to place them on roller conveyors which feed the drums to the drum fillers.

In case of pallet fillers where the drums will be filled on pallets, the robot can even exactly position the drums on CP3 or CP9 pallets.

Having unstacked the drum rows, the robot will put down the slip sheets and the pallet. These sets of slip sheets and pallets can again be stacked so that the return from the filling company to the drum manufacturer will not require much space.

Hall 3.0, Booth K17

cpp 401

Die Homepage von Feige Filling

Markt für Container, Paletten und Behälter

Achema 2006

Share: