Extracting oil or gas is complex, time-consuming and expensive. This is especially true in exploration and transport regions where low temperatures are the norm due to geography, such as in Alaska, Canada or Russia for example. Resistance to low temperatures is an essential prerequisite in this kind of climate, where elastomer seals soon come up against limitations.

All boreholes have one thing in common: the demands on the materials and components used there are extreme. For instance, drilling heads must be able to withstand high drilling mud pressure, strong pressure fluctuations and aggressive chemical substances. During deep (downhole) drilling, the materials must be capable of resisting high pressures at the same time as high temperatures of up to 200 °C. If unsuitable elastomer seals are used in these applications, for example in the valve controls for the motors or actuating mechanisms and measuring instruments, an entire machine unit can be damaged, so that all extraction work must be interrupted. The problem here is that, during drilling activities, the drilling head and the complete drive technology can only be monitored to a very limited extent and it is not easy to replace the seals at depths of more than 2500 m. Production stoppages under such extreme conditions are disastrous because the downtime eats into productivity and profitability. The daily running costs for the platform and the crew total around 200,000 euros and can sometimes rise to 500,000. All components must therefore work absolutely reliably.

Apart from exploration, other typical applications for elastomer seals include transport, storage and processing of oil and gas as well as the subsequent manufacture of chemical and petrochemical products. These all involve the use of a wide variety of technical components and assemblies. Elastomer seals can be found in the drive motors for the drilling heads and also in gas filters, valves, pipelines, fittings, pumps and compressors, where they are regarded as key, safety-relevant components.

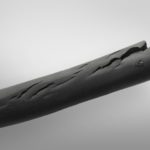

Explosive decompression

Many operators in the gas and chemical sectors, along with component manufacturers, tend to experience problems with elastomer seals leaking, especially when there is loss of pressure. This primarily affects seals acting against gaseous media

if the gas drops from a high to a low pressure level within a short time. The damage this process causes to the elastomer seal is readily visible, for example because bubbles form on the surface. This phenomenon is known as explosive decompression.

Only specially designed and tested elastomers can be used for these applications, because conventional alternatives do not demonstrate sufficient resistance

to the forces that occur there. So-called

AED (anti-explosive decompression) or RGD (rapid gas decompression) seal materials, on the other hand, are able to withstand even the harshest conditions. An elastomer seal’s resistance to explosive decompression can be certified by testing to Norsok M-710 Revision 3 (Annex B) and/or ISO 23936-2.

Tailor-made for oil and gas

In very cold regions, the low temperatures pose another major challenge for elastomer seals in addition to the extreme demands already faced. It makes no difference whether the seals are fitted above ground in cold ambient temperatures or used continuously in the pig traps or valves of pipelines, for instance. Most elastomer seals – especially those made from FKM, which predominate – are often not very suitable for use at temperatures below -25 °C. Only special FKM materials can be employed in these conditions. However, these are not generally AED/RGD-resistant, nor are they particularly resistant to chemicals.

C. Otto Gehrckens, or COG for short, has developed an FKM compound specifically for these applications and subjected it to intensive testing. The FKM material Vi 900 passed the Norsok standard M-710 test with the best possible result, namely “0000”. Furthermore, this high-performance FKM also fulfils ISO 23936-2 requirements for resistance to explosive decompression. With an operating temperature range from -51 °C (TR-10 value -40 °C) to 230 °C, this seal material is also ideal whenever large temperature fluctuations are likely. The FKM material Vi 900 is hence approved for use in components or modules where the valve industry’s API 6A and 6D standards apply and a design temperature of -46 °C is stipulated. The material profile of this extremely chemically resistant FKM compound is rounded off by the industry-relevant NACE TM 0187 (acid gas) stand-ard. It is precisely this combination of chemical and AED resistance coupled with low-temperature flexibility that makes this cold-climate sealing material such an interesting option for design engineers and operators confronted with extreme technical challenges in the oil and gas industry.

C. Otto Gehrckens GmbH & Co.KG, Pinneberg