Whether storage tanks, columns, pipelines, pumps or valves – each component requires a separate solution with regard to protection against corrosion. A comprehensive range of applications in chemical plant construction can be realised with modified PTFE and PFA types, which offer comparable corrosion protection potentials but different processing technologies.

Authors Dr. Gabriele Gottschalk-Gaudig Application and Product Development Europe Fluoroplastics, Dyneon Wolfgang Neumann Application and Product Development Europe Fluoroplastics, Dyneon Dr. Michael Schlipf Consultant at Dyneon

Lining materials to protect plants consisting of steel or fibre-reinforced plastic structures effectively against corrosion and chemical attack, should exhibit universal resistance to chemicals. This is the case with fully fluori-nated fluoropolymers such as 3M Dyneon PTFE, 3M Dyneon TFM modified PTFE and 3M Dyneon fluoroplastic PFA because the potential weak point of the polymer material – the carbon chain – is optimally protected against chemical attack by the fluorine atoms arranged on all sides. These also prevent ageing processes such as embrittlement in the fluoropolymer materials and provide constant material properties over the entire lifecycle. That is one of the main reasons why fully fluorinated fluoropolymer materials are predestined for corrosion protection applications with additional Atex requirements. The difference between the three materials lies in their molecular weight and their content of perfluoro (propyl vinyl ether), a similarly perfluorinated comonomer that is used in the manufacture of TFM and PFA. The molecular weight and thus the viscosity of the polymer in the molten state are reduced in the PTFE – TFM – PFA series. This gives rise to the good particle melting of the sintered TFM material; thanks to a further red-uction in the molecular weight, PFA can be processed by thermoplastic methods. The lower void content of TFM produces a maximum barrier effect against aggressive chemicals, while PFA is practically free from voids.

Material properties

So what role does the modifier PPVE play in balancing the property profiles of these materials? As semi-crystalline materials, these fluo-ropolymers obtain their strength via the amorphous portion of the polymer matrix, unlike all non-fluorinated semi-crystalline thermoplastics. The crystalline portion of the polymers will now rise significantly in the PTFE – TFM – PFA series, since the ever shorter macromolecules can fold more easily to form crystallites. The likely consequence of this will be the loss of mechanical strength. With its voluminous side chain, however, the modifier PPVE disturbs the growing tendency of the shorter molecule chains to crystallise and in doing so increases the amorphous portion of the polymers and improves their mechanical properties. As a result, the user avails of a product portfolio the representatives of which have virtually identical and universal resistance to chemicals but differ significantly with regard to their processing and joining methods, and thus enable universal corrosion protection solutions in complex plants. One of the decisive criteria when selecting the most suitable fluoropolymer for an intended corrosion protection application is its barrier effect towards corrosive chemicals. The determining material features that affect permeation behaviour are freedom from voids, crystallinity and polarity. Design criteria and the conditions of the application, e.g. the layer thickness of the polymer lining or the usage temperature, are also important.

Protection using the fixed bond method

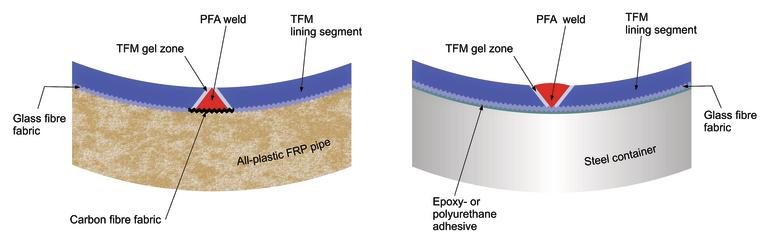

For corrosion protection tasks at temperatures from ambient up to about 120 °C, for example as required for storage or transport containers or in isolated cases also for chemical reactors, the fixed bond method has proven to be the best solution. In order to bond the fluoro-polymer lining segments permanently to the steel structure, they must first be provided with a layer that can be adhered. This is done by laminating a knitted glass or carbon fibre fabric and then firmly bonding the laminate to the steel structure using an epoxy resin or polyurethane adhesive. Since the fully fluorinated fluoropolymers exhibit a coefficient of expansion of approximately 12 x 10–5 1/K – about ten times higher than steel – shear stresses occur between the layers of the composite material as the temperature changes. This type of corrosion protection is restricted to applications in the temperature range from 0 to around 120 °C, on the one hand by the requirement for a secure adhesive bond in combination with vacuum resistance and on the other by the lim-ited temperature resistance of the chemical-based adhesive systems available on the market. In particularly favourable cases, fixed bonds are also possible up to approximately 140 °C. The different processing methods for TFM and PFA, which are the base materials, determine the laminated products. Whereas PFA laminates are manufactured using the sheet extrusion method, in the course of which the fabric backing is pressed into the still soft polymer melt, TFM laminates are produced in a two-stage process. First of all, the single-layer film is created by slicing it from a pressed and sintered TFM block, then the fabric layer is attached to one side by hot pressing. Due to the process, therefore, PFA laminates exist as rolled goods with a typical thickness of 1.5 or 2.3 mm, or up to 3.8 mm on request, whereas TFM laminates can be up to about 5 mm thick thanks to a special slicing process (the laminate thicknesses specified for the lining refer to the fluo-ropolymer layer without fabrics).

All-plastic containers made from glass or carbon fibre reinforced plastics are used mainly for manufacturing, storing and transporting ultra-pure chemicals. The glass or carbon fibre reinforced outer structure ensures mechanical stability and is firmly joined to the fluoropolymer liner via the latter’s fabric backing. Laminates based on both PFA and TFM are used for this application, depending on the requirement profile.

Protection using the loose bond method

A fixed bond is frequently not possible for corrosion protection of plant components with a complex geometry. This includes the linings of pumps, valves, measuring sensors and various other components. These are effectively protected against corrosion by so-called loose bond lining systems, in which the fluoro-polymer liner is fixed by mechanically anchoring it to the (usually metal) housing. The PFA transfer moulding method is suitable for assemblies with particularly demanding and complex geometries. Here, the melted PFA mass is transferred to the fitting to be lined using transfer presses, where both the polymer melt and the metal part to be filled are at the same temperature. Cooling takes place only after complete filling via an internal core, which defines the thickness of the lining. The PFA liner and the metal housing are joined together both by clamping the PFA flanges in the flange area and face to face by means of so-called dovetail joints. Alternatively, components with a simpler geometry, e. g. pipe elbows or branches, can preferably be lined by the isostatic press method using free-flowing TFM. Paste-extruded PTFE/TFM liners are established as the standard for long pipes.

Apart from the complex geometries of plant components, high operating temperatures >120 °C are another reason to select a loose bond lining system. Chemistry columns, washers or other large-sized special components are therefore also lined according to the loose bond method. Both paste-extruded pipes and sliced films based on modified PTFE are utilised here as lining materials. Thanks to mature welding methods for both PFA and TFM, there are almost no limits with regard to design flexibility. The owner of the plant is responsible for ensuring proper insulation and rear ventilation of all components which are protected against corrosion by the loose bond method, especially those used at high operating temperatures. Only these additional measures can reliably prevent the formation of blisters in the lining material as well as rear rusting between the lining and the steel structure on a long-term basis.

Joining technology

PFA in sheet form or as a laminate can be joined very effectively by butt welding with heating elements. However, this method is only suitable if the plates to be joined are accessible from both sides, for example when manufacturing the liners for fluoropolymer-lined fibre-reinforced plastic containers. The thermoplastic properties of the PFA allow a comparatively high welding speed. However, welding methods are now also available for TFM with excellent results as regards strength and impermeability. Plates up to 5 mm thick or more can be butt welded with heating elements without having to use an auxiliary welding material. Weld strengths with a factor >0.8 are attainable. Hot gas welding with PFA welding filler is used for TFM materials whenever butt welding with heating elements is not possible.

PFA and TFM together with PTFE and FEP form the product group of fully fluorinated fluoroplastics. Components made from these materials can be returned at the end of their lifecycle and fed to the Dyneon up-cycling pilot plant, where they are ground and split into the monomers TFE and HFP. After cleaning, they are reused in the familiar polymerisation processes.

Hall 9.0, Booth E36

cpp-net.com/0215470

Share: