Tubmaster from Mycon gently cleans shell-and-tube heat exchangers and individual tubes with compressed air and dry ice or various granulates. Blasting media and residues can be collected cleanly by means of a downstream extraction system with filter unit and filled for disposal or reuse. Tubemaster is often used when other cleaning methods have not been successful or when wet cleaning is not desired or not possible.

That was the case in an acetylene production. Cleaning attempts using extreme pressure cleaning with water of 2500 bar were unsuccessful – Tubemaster AS, however, was able to get the job done.

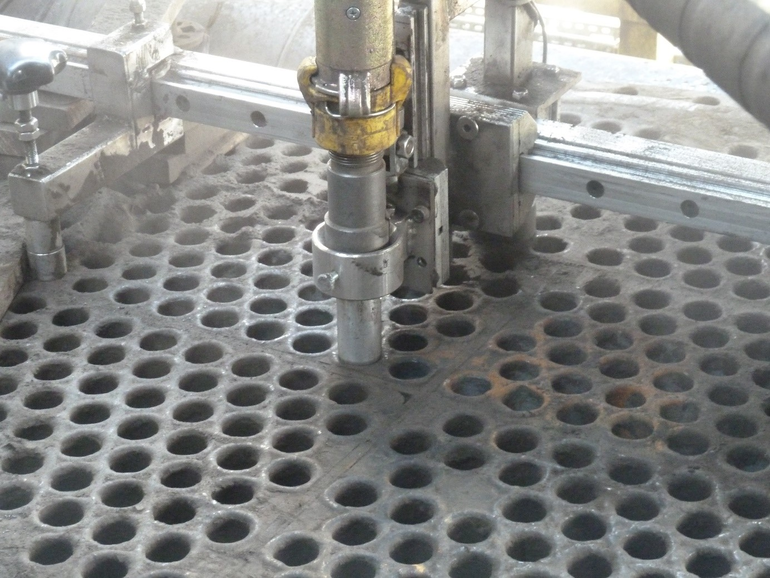

The cleaning method Tubemaster AS was able to successfully clean tubes of 8 m of tube bundle heat exchangers using only 6.5 bar jet pressure. The automated cleaning unit was set to the required cleaning speed. Thus, the entire cleaning process occurres uniformly with the same parameters which leads to high-quality cleaning results. Due to the residues being unusually and firmly stuck to the surface, each tube is cleaned twice and eventually examined with a special-purpose camera.

The inner surface of the tubes (38 mm) partly exhibited extremely hard and irregular residues of 16 mm in thickness. These residues built up over several years. Earlier cleaning attempts per high-pressure water cleaning with up to 2500 bar remained unsuccessful. Due to the residues in the exchanger, production was severely impaired. Additionally, the necessary energy expenditure for the cooling process increased drastically. Replacing the exchangers would have been very time-consuming considering the procurement cost as well as the installation and the production downtimes involved.

Prior cleaning tests successful

Prior cleaning tests via Tubemaster AS already proved to be successful. Thereupon the customer granted the company Kipp Umwelttechnik their entire cleaning order for the application of Tubemaster AS. For years Kipp Umwelttechnik has worked with devices of the company Mycon exclusively and is therefore well-experienced in this regard. The entire execution had to be carried out under the guidance of explosion protection directions. Kipp Umwelttechnik used Tubemaster AS as a completely closed procedure. Residues and operating funds were extracted during the closed process, immediately collected and made available for proper disposal.

For vertically or horizontally cleaning

Tubemaster AS can be used for cleaning vertically or horizontally arranged tube bundle heat exchangers. It can be transported through manway openings without difficulty. Furthermore, for the cleaning of individual tubes special articles for coupling connections are delivered as well. Operating the machine is definitely trouble-free and require just two members of staff.

The abrasive used depends on the type and nature of the residues, the tube routing and the tube material. Tubemaster can also clean curved pipes with dry ice and/or special granulates. The nozzle is guided through the tube to be cleaned at the speed required to remove the residues by means of a special adapter which is pressed manually or automatically onto the tube mouth. If special granulates are used that are matched to the pipe material, the inner pipe surfaces can be additionally polished.