Chemical plants need to be operated at high temperatures under rapidly changing load parameters. These modes of operation may expose plant components to higher stresses, resulting in degradation caused by pressure and/or thermal loads. Degradation mechanisms acting on components include creep and fatigue, which are also referred to in technical literature as high-temperature progressive deformation and progressive and localised structural damage under cyclic loading respectively. The combination is known as creep fatigue and referred to in this article as exhaustion or the state of exhaustion. While creep is caused by static loads and depends on temperature and internal pressure, fatigue is caused by cyclic loads. In the case of changes in temperature, fatigue increases in parallel to the rate of temperature changes. This is due to the following mechanism: as the thermal conductivity of the material is limited, steep temperature transients result in increasingly high temperature differences inside the component wall, which in turn give rise to mechanical stresses.

The impacts of these stresses are hardly detectable because they first become apparent at the component’s inner surface, where they are difficult to identify by non-destructive test methods (NDT). Identification is only possible if the component is already affected by incipient cracking. Defects and failures are the result, even though the responsible parties assumed they had taken reliable precautions in the form of NDT. Many of these defects and failures could have been prevented by needs-based calculation of component life.

TSE for stress-strain analysis

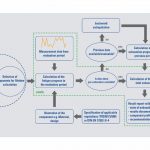

The TSE (temperature stress exhaustion) software calculates component exhaustion (fatigue and creep) based on pressure and temperature curves. The program uses algorithms aligned to the specific regulations and standards in encapsulated functions and is fully in conformity with the applicable codes and standards. The reports of the results thus also provide a reliable legal compliance report.

Input data required by the software include data on component geometry and materials in addition to the measured temperature and pressure loads. TSE uses integrated non-stationary calculation of the temperature field to model the non-linear distribution of temperature across the component wall for a close network of interpolation points at any point in time throughout the analysis period. The software is also able to process temperatures measured on the component exterior and eliminates the need to perform temperature measurements on the interior wall of the component or the fluid, or even measurements of the temperature difference including determination of the temperature inside the wall.

For plants in Germany, data analysis is aligned to technical regulations and standards harmonised across the EU. Using offline evaluation of the measured and saved data, the solution delivers proof of whether component exhaustion is below the critical thresholds defined in DIN EN standards. The intervals of this type of creep-fatigue life analysis should be based on the state of exhaustion determined in the most recent previous analysis and the mode of plant operation. TÜV SÜD recommends annual evaluation cycles to ensure timely inclusion of new load phenomena in the evaluation.

Offline evaluation offers significant benefits, particularly in the as-is analysis of the stresses acting on the component which is part of the first step of the evaluation, because monitoring over longer continuous periods enables stress patterns to be identified. Appropriate pattern recognition routines have been implemented in the TSE program. They enable critical load events to be allocated reliably and – where necessary – changes to be initiated in the mode of operation for the purpose of reducing loads. In step two of the evaluation, the program determines the actual state of component exhaustion and the fatigue reserves of the components available at this stage. The TSE software thus provides information about the remaining number of load cycles and the extent to which further changes in the mode of operation can be realised.

In a third step, the program models the fatigue progress resulting from new transient configurations and accumulates it with the degree of fatigue from previous operation. This approach allows experts to define optimised transients that ensure consistent use of fatigue reserves while keeping component exhaustion below critical thresholds. The software is thus designed to determine values that are as realistic as possible, while preventing the introduction of additional safety margins that are not justified from a physical perspective and not required by standards and regulations.

Evaluating creep-fatigue realistically

The calculations performed by the TSE software do not use the temperature inside the component wall, but the physically correct integral mean wall temperature. If the program used the temperature inside the component wall, the calculated Delta T would be excessive, resulting in 50 % higher fatigue values. This is one example demonstrating that the phenomenon of fake fatigue can be avoided by relying on realistic analyses instead of more conservative methods – a step for further improving the flexibility of plant operation. The objective should not be to keep component exhaustion to a minimum, but to achieve controlled component exhaustion in line with the available fatigue reserves. To this end, experts could also carry out predictive “what-if” analyses calculating the respective progress of component exhaustion for different operating transients.

Case study: steam crackers

TÜV SÜD was commissioned to evaluate the condition of the reactor pipes of a steam cracker. A steam cracker contains pipe coils with inside diameters of 90 to 120 mm and lengths of 60 to 80 m which are installed in a furnace-heated combustion chamber. Steam crackers use process steam to break down long-chain hydrocarbons into smaller unsaturated hydrocarbons. Process temperatures are extremely high (850 °C).

The experts started by evaluating the available information about component temperatures in the past to build a basis of reliable data providing information about components’ lengths of exposure to specific temperatures. Other essential data concerned the geometry and materials of the components. These data were found in the installation documentation maintained by the plant manager. Next, the experts carried out a preliminary sensitivity analysis to identify which components were inherently affected by progressive degradation caused by temperature and pressure. For these components, the actual progress of degradation was then calculated by the TSE software based on specific evaluation of temperature and pressure data and considering the specific data of component geometry and material. The results delivered basic information not only about the state of exhaustion of individual components, but also about the state of the system and the transients that are particularly significant in fatigue progress. The experts also provided the plant manager with suggestions on how to reduce component load, and gave recommendations for condition-based NDT measures.

Firma mit Firmierung, OrtTÜV SÜD Industrie Service GmbH, München