Lyophilisation, or freeze-drying, is a pivotal process in clinical diagnostics for stabilising biological substances. It enhances the stability, storage, and transport of reagents. Currently, there are three major form-factors for lyophilized products used in clinical diagnostics:

- Cake: A flat, disc-like structure produced by lyophilising a solution in shallow containers (e. g. microplates). Its thickness and diameter vary based on application needs. The cake can be broken up or dissolved (reconstituted) to obtain the desired concentration of the reagent for use.

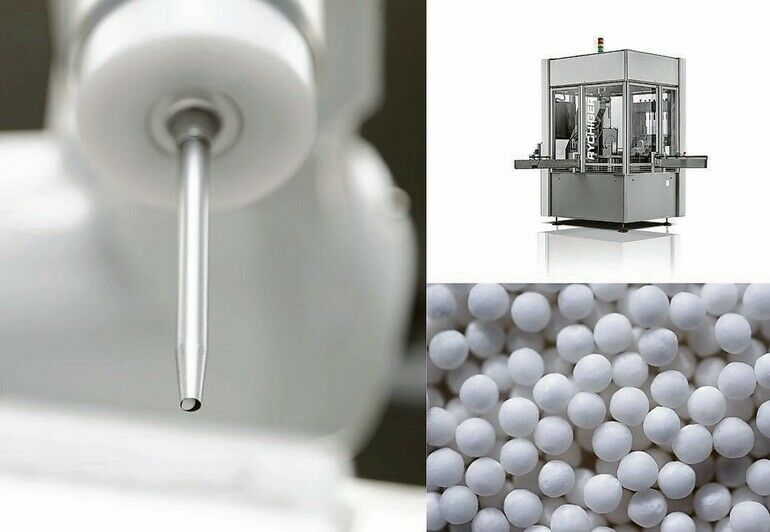

- Microspheres: Spherical particles of 0.3 to 0.8 mm diameter, created in a cold tunnel and drying drum, offering increased surface area, better dispersibility, and ease of handling due to their form.

- Spheres: Larger spherical structures of 1 to 6 mm in diameter, formed by dispensing liquid reagent into cold molds or liquid nitrogen before freeze-drying.

After lyophilisation, reagents are sealed in airtight containers to prevent moisture absorption, ensuring stability and shelf life during storage and transport.

Handling of cakes

The process includes picking and placing cakes into medical devices, preventing them to shutter. Presence checks via cameras ensure the quality of the process at every step of the process. When introduced into Rychiger’s filling lines, an actively controlled low-humidity environment ensures the quality of the lyophilised material. This is crucial for the shelf life of the diagnostic device. Some of the diagnostic devices are vacuumized before sealing, others are flushed with N2 or dry air.

Singulation of (micro-)spheres

Singulation separates individual (micro-)spheres from bulk for processing. The bulk is dispensed into a singulation-friendly container, such as a conveyor belt or tray. Rychiger‘s methods are efficient, gentle to the spheres and accurate in positioning. Also, here camera-based quality checks can be used to determine the presence and correctness of the position of each sphere in the medical device.

Gravimetric dispensing

Gravimetric dispensing of lyophilized spheres requires precise measurement and transfer of a predetermined weight from bulk supply to individual containers. Challenges arise due to the fragility of the spheres, necessitating careful management of shear forces, compression, humidity, and static load throughout the process. Weights as light as 1 mg, varying based on factors such as reagent concentration, assay sensitivity, and sphere usage, are typically required, ranging up to hundreds of mg.

Rychiger

Hall 3.0, Stand B25