Firmen im Artikel

The measurement of several phases, so-called multiphase levels, poses some challenges for the manufacturers of process measuring instruments. In addition to the often indistinct interfaces, these include the (sometimes only slightly) different phase densities. Multiphase level measurements are used wherever a live image of the highly complex separation process in a vessel is required in order to adapt certain process parameters. Separators, storage tanks, desalters and hydrocrackers are typical applications. It is clear from these diverse uses that multiphase level measurements are frequently employed in processes operating under extreme conditions, so that radiometric measurements are indispensable. The measuring principle is based on the attenuation of radiation when penetrating materials. This is virtually independent of other process conditions such as vessel size, build-ups or internals.

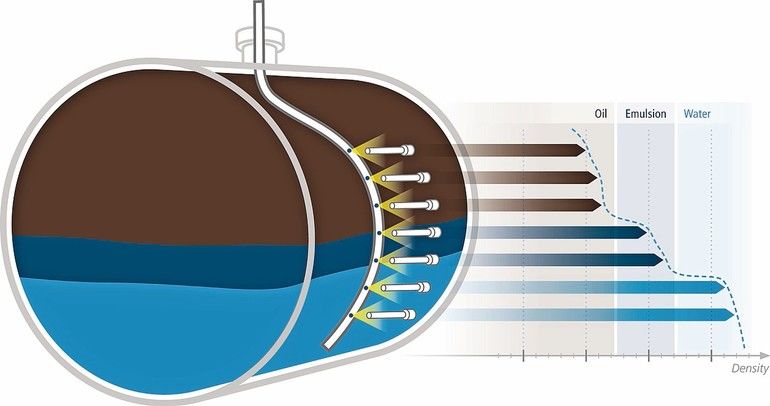

The Emulsionsens system gives users an

opportunity to get a glimpse inside the process vessel and monitor the interfaces

formed therein. The multiphase level measurement system consists of a combination of high-sensitivity scintillation detectors and low-activity gamma sources located along the desired measurement range. Based on the radiometry principle and suitable calibration, each detector delivers an individual local density value, which can be forwarded to the customer’s process control system by means of a Hart signal and used to create a density profile for the entire measuring range. The figure shows the measuring principle of Emulsionsens for a desalter and the resulting density profile. By mounting the detectors on the outer wall of the vessel, they are easily accessible and adjustable. One-time calibration of the system as part of initial commissioning is sufficient, in other words no recalibration is required. Since no mechanically moving parts are installed and the sensors are not in contact with the material to be measured, radiometric systems are wear-resistant and maintenance-free. Due to the curved dip tube which is used to position the encapsulated sources, the length of the measurement path is almost identical regardless of the position (500 mm) and as much material as possible is measured, so that a representative measurement and image of the density profile are obtained. Both the long measuring path and the use of high-energy gamma sources (e. g. Cs-137) mean the measurement process is insensitive to build-ups on the container wall and the dip tube. As the shield is mounted on the vessel, the sources can be removed from the dip tube – for example for maintenance work – and stowed safely, so that from the point of view of radiation protection safe entry into the vessel is ensured.

Emulsionsens also ships with a connection for an evaluation unit. Based on the density profile, this unit uses internal algorithms to determine the position of the individual interfaces, which it provides as 4…20 mA current signals in addition to the individual density values of the detectors. Apart from the advantage of redundancy, the evaluation unit also displays the measured values in real time. Bar graphs and time histories of the phase densities enable a quick overview of the desalter prior to adapting important control parameters. Emulsionsens can thus reduce the probability of malfunctions and at the same time increase the throughput of the desalinator which leads to better control of the separation processes.

Online search: cpp0319berthold