Firmen im Artikel

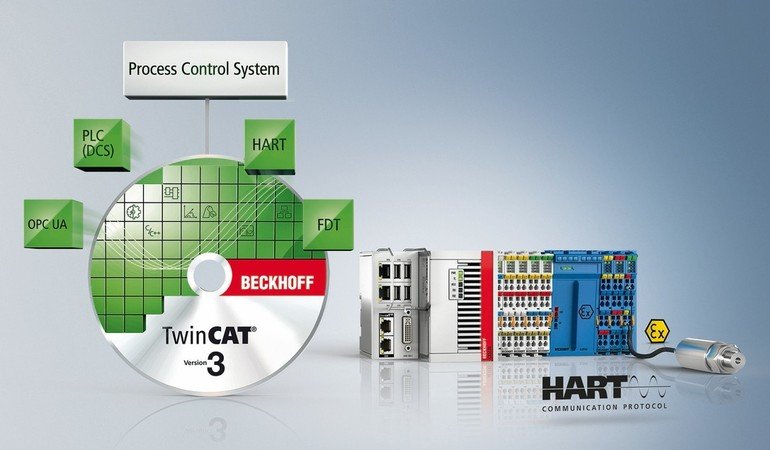

PC-based control from Beckhoff integrates process-specific protocols and interfaces, and offers an extended range of products for hazardous areas. Full implementation of Hart functionality, both in the I/O system and in the TwinCAT engineering environment, promotes simple project planning and reliable commissioning. TwinCAT automation software reduces development efforts in process technology because it facilitates the application of Hart functions directly from the engineering interface. In this way, the TwinCAT FDT container enables implementation of any field device drivers (DTM). Thus, an entire Hart configuration can be implemented using a single tool. The CommDTM integrates the TwinCAT platform into existing process control systems. With its help, the DTMs can be implemented in any FDT container. This applies to all field devices connected to the Hart-capable EtherCAT terminals. These devices can be configured and parameterised remotely in the known containers without requiring direct PLC access.

Online search: cpp0118beckhoff

Hall 9, Booth F6