Coriolis flowmeters are real multitalents. A special function called fraction measurement enables the quality of products to be improved even more and the economic efficiency of plants to be enhanced.

The author: Hans-Juergen Huber Manager of I IA SC Industry Business Development CHem/PetroChem/O&G, Siemens

A large number of electronic flowmeters in the chemical industry are already operating according to the Coriolis measuring principle. This is no surprise, since it is suitable for practically any kind of medium, whether gaseous, fluid or pasty, conductive or non-conductive, and can even be used for aggressive acids and alkalis. A further big advantage of this technology is that the devices supply stable results even when the temperature or pressure fluctuates.

The multivariable device continuously supplies mass flow and volume flow, density, concentration and temperature of various substances. Whether filling, dosing or quality control, it is hard to imagine the chemical industry nowadays without Coriolis devices such as the Sitrans FC from Siemens. Particularly in this industry the manufacturing process comprises many intermediate products that continually need to be checked for quality, for instance, at the output of a reactor vessel. Quite often, density is suitable for use as a parameter for checking quality. If this moves out of a defined range, action can be taken early on to correct the process. Another advantage of Coriolis is that the inline density measurement enables users to check the quality of their products directly in the process without the need for an additional density measuring device and without extra time and cost.

In the chemical industry the product to be measured often consists of two different substances. In this case, it is particularly interesting for the user to obtain information about the percentages of the two material flows. Thus it is possible, for example, to check how high the water content is in paraffin production by means of fraction measurement, a function that is already integrated in the device. This clever additional function enables the plant to operate closer to the optimum.

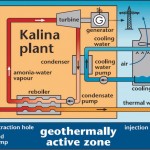

The example of the Unterhaching geothermal power plant below shows how fraction measurement of a two-component mixture of water and ammonia can enhance the eco-nomic efficiency of a plant

Small trick, big impact

The geothermal power plant generates electricity using a steam turbine. But the source of thermal water is not hot enough to operate a conventional water-steam cycle. That is why in this case, a special process called Kalina process after its Russian inventor is used. What is the trick: Instead of thermal water, a mixture of ammonia and distilled water is used, which boils at 50 °C itself. Ammonia evaporates at significantly lower temperatures and increases the efficiency of the heat exchanger. Particularly in case of low temperature sources such as the one in Unterhaching, a considerably higher efficiency can be achieved by using the ammonia-water mixture in steam turbines in the small power plants.

Sophisticated process

The heart of the plant is unquestionably the turbine, which drives the generator for electricity generation. Nothing works without it. For an optimum operation, the ammonia-water mixture must on one hand have the highest possible temperature and on the other a high-est possible pressure. The 122 °C hot thermal water heats the mixture in the evaporator from 55 to 115 °C. The required pressure is built up by a pump. It increases the pressure of the working medium to around 20 bar. Residual fluid, if any, is separated in a high-pressure separator. The vapor mixture thus compressed and heated is lead through the turbine. The working medium leaves the turbine at approximately 7 bar, still in the form of vapour, and is cooled down in a smaller heat exchanger. The low-pressure separator collects the residual fluid, a cooling water system lowers the temperature of the steam until it reliquifies. After a condensate tank, the mixture is again compressed to 20 bar and preheated in the smaller heat exchanger to 55 °C before being relead into the evaporator.

Deviations from the mixing ratio of the ammonia-water mixture have a direct impact on the efficiency and hence on the economics of the entire plant. The data must be captured in real time to be able to respond quickly and effectively to the possible deviations. This, however, means that the measuring instrument responsible for it must be integrated in the process control system of the plant – in this case Simatic PCS7. The monitoring of the mixing ratio is elementary. But how can one anyway measure the mixing ratio of two fluids in a pressure cycle? That too preferably with a single measuring instrument? Moreover, the operators wanted a cost-effective, reliable, accurate and, not the least, low-maintenance solution. An answer was found quickly: amass flow measurement according to the Coriolis principle.

One device, several possibilities

In this method, the flow sensors are actuated through an electromechanical field circuit, which excites a pipeline to vibrations in its natural frequency. In his case, two sensors are placed symmetrically on both sides of the exciter. If fluid or gas flows through the flow sensor the Coriolis force acts on the measuring tube, which affects every object whose motion is described in a rotating reference system. It causes a deflection of the tube, which can be measured on both the sensors as a phase shift proportional to the mass flow rate.

In addition to the sensor signals, temperature value and exciter frequency are fed into the transmitter. Sitrans FC provides free house values for density, mass, volume, temperature as well as fraction.

Passed the Litmus test with flying colours

In Unterhaching, it is therefore important that the water content in the ammonia can be measured reliably. Since the mass flowmeter can firstly measure the weight and secondly the density of the ammonia-water mixture, the respective mass fraction of the individual components can be calculated from the values of the mixture. In this respect, the transmitter Sitrans FC falls back on a very special function: fraction measurement. This requires that the specific densities of both media must be known within the expected temperature measuring range. For a high reliability of the calculated results, at least five different densities of ammonia and water are entered in a special calculation program. A polynomial calculation is performed five times , the result of which is then stored as a software function in the transmitter. The PT1000 temperature sensors installed in the Sitrans FC measure the exact temperature of the mixture and form the basis of the temperature compensation for the exact calculation of the respective densities and masses. With skillful application of the described functions, an accuracy of 0.15 % can be achieved for density and mass with the series Massflow Mass 2100 DI3–40 for ammonia and distilled water.

Versatile and economical

The advantages for the customer are clearly obvious: In place of one device for temperature measurement, one device for measuring density and one device for flow measurement, he only requires a single measuring instrument. The Coriolis flow meter offers considerable cost benefits during acquisition as well as maintenance. Typical wear parts? Not applicable. Moreover, the installation and engineering cost is significantly lower, since only a single device needs to be integrated in the pipeline. This saves a lot of time and cabling costs during commissioning. The reliability and accuracy of the measured values provides for an efficient operation of the turbine and as a result increases the efficiency of the plant significantly.

Online-Info: www.cpp-net.com/2211438

Share: