Firmen im Artikel

Protecting plants in the chemical and pharmaceutical industry from downtime involves considerable effort. Compared to factory automation, where the focus is on higher unit quantities and shorter cycle times, the interruption of a continuous production process can lead to enormous financial losses. Furthermore, the handling of hazardous liquid or gaseous substances involves the observance of strict safety precautions – particularly in areas provided with explosion protection. As a preventative measure, companies therefore firstly invest in the safeguarding of potential ignition sources and secondly in a high availability system architecture. Controllers and I/O modules in the field are normally provided with redundancy in order to ensure safe plant operation. If one device or connection fails, the otherwise inactive backup solution is activated. Planners implement these complex or limited redundant systems in accordance with the relevant requirements – both on the physical device level as well as in the underlying programming logic.

S2 system redundancy preferred

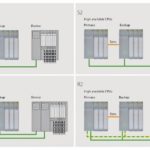

In the Profinet context, a new standard was created for this with system redundancy. The terminology used here is based on a gradation that reflects the degree of fail safety that an automation system is to provide. No redundancy is implemented (S1) if a controller and field device only communicate via a single connection. However, if a Profinet device supports communication relations to the primary controller as well as its backup via this single connection, this is classified as S2. In the event that the main controller fails, a bumpless switching to its physical twin is performed. For this, the I/O system and I/O module in the field must maintain this logical dual connection to two entirely spatially separated controllers. These S2 solutions meet the requirements of many applications and are preferred in practical applications. The alternative term “simple system redundancy” should not obscure this fact.

Very high and maximum availability can only be achieved with R1 or R2 system redundancy. This involves the additional implementation of a redundant communication interface on a field device, and is often used in conjunction with remote I/O. R2 with its four-way connection represents the highest level of complexity. Here, each of the two communication interfaces of a device can establish communication relations – to the main controller and to its redundant copy. This crosswise protection from failures is used extremely rarely.

High availability to the field

Siemens initiated the Profinet implementation of the redundancy profile and designed its controller systems to support redundant infrastructures. Profinet devices had previously not provided support for S2 system redundancy. Turck is now responding to this demand with an extensive expansion of functions.

The TBEN-L5–8IOL will be the first IO-Link master module that supports S2 system redundancy and offers protection to IP 67 and IP 69K, thanks to its fully potted electronic unit. This combination of Industrial Ethernet and IO-Link offers digitalisation right through to the last meter. Furthermore, Turck‘s I/O modules come with an additional TCP/IP interface for read access to device data, so that all digital treasures can be gathered. Condition monitoring, asset management and predictive maintenance can thus be implemented without any limits.

Turck is also offering SIDI (Simple IO-Link Device Integration), probably the most user-friendly way of integrating IO-Link into Profinet projects. IO-Link masters with SIDI give IO-Link devices the identity of a genuine Profinet module with their own GSDML entry. The function considerably simplifies the engineering of IO-Link devices in projects with Profinet controllers, since it allows access to all parameters and device properties from the engineering system without the need for additional software.

Use in practice

The first TBEN-L5–8IOL modules will soon be deployed in the USA in the plant of a biopharmaceutical manufacturer, which will manage its production with Profinet system redundancy and IO-Link in the future. High availability is essential for the handling of mostly sensitive and cost-intensive products. An integrator in the pigging technology sector found the additional profile support for IP 67 devices equally important. The company serves customers in the chemical, pharmaceutical and mineral oil sector. The high protection class of the TBEN field devices now simplifies the planning of systems in these sectors. Decentralized and modular network architectures can be designed so that the space required in the control cabinet is substantially reduced.

The IO-Link master is at the beginning of the major product upgrade to S2 system redundancy. Over the year, Turck will provide other multiprotocol devices with the additional function, and block modules of the TBEN series will follow, as well as the IO systems for the control cabinet of the FEN20, BL20 and excom series. The changeover to Profinet with a wide range of signal types, both for the Ex and the non-Ex area, can thus be completed without any obstacles.

Online search: cpp0319turck

Author: Aurel Buda

Director Product Management

Factory Automation Systems,

Turck