Firmen im Artikel

In sewage treatment plants, one treatment stage immediately follows the next. Each of these processes must be perfectly coordinated with the previous and the subsequent one so that the overall system can work optimally. To control the various process stages automatically, precise measurement data are required. But accuracy is not everything. Smooth, trouble-free operation is only possible with robust, durable sensors that can withstand wind, weather and the challenges posed by dirt and contamination.

Compact and highly accurate

For decades, the Schiltach-based company Vega has been supplying a wide variety of level and pressure sensors to sewage treatment plants all over the world. At the beginning of this year, a new compact series of radar level sensors was introduced to the market. The beating heart of these new sensors is a radar chip newly developed by Vega and specially optimised for the requirements of level measurement. And thanks to its small size, very compact sensors are now possible. Moreover, these new instruments are so inexpensive that they can replace previously-used ultrasonic sensors in almost all applications. Vegapuls series C 11, C 21 and C 22 sensors have a fixed cable connection and are designed in protection class IP 66/IP 68. In accordance with the requirements in the waste water sector, the sensors are also suitable for use in Ex hazardous areas up to zone 0. And for the typical zone 1 in the wastewater industry, Vega has come up with something special. By means of a special encapsulation, which is new for radar sensors, operation in Zone 1 is possible even without an intrinsically safe power supply – making installation much easier for the user.

In addition to being unaffected by temperature fluctuations, vacuum or changing gas overlay, radar sensors are, most importantly, non-insensitive to soiling. These are all factors that often lead to malfunctions in ultrasonic level measuring devices. The Vegapuls series measures with a frequency of 80 GHz, which enables very good signal focusing. With this advanced technology, measurement signals can be better separated from interference signals − the measuring process itself thus becomes much easier and more precise than other measuring methods. Before its official market launch, the new sensor series was tested in over 400 applications in 30 countries. Several application examples in the wastewater industry show where the new sensor can really unleash its strengths.

The basis for calculations

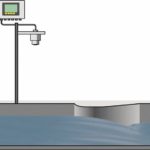

Waste water and rainwater are transported to the waste water treatment plant via widely branched sewer networks and measured in open channels on the way to the plant inlet. An important job, since measuring the amount of water flowing in and out of the plant provides the basis for calculating service rates and fees as well as operating costs. The Vegapuls C 21 delivers these measured values reliably with an accuracy of ±2 mm, regardless of the ambient temperature and the type of medium.

The sensors are also used at another point on the way to the waste water treatment plant – in pumping stations. If the natural gradient from the households to the plant is not steep enough, various pumping stations are required to create sufficient height differences along the way. Level measurement with Vegapuls C 11 in the inlet shaft of the pumping station, together with a controller, ensures economical operation of the pumps.

The rain overflow basins, which protect waste water treatment plants from overload during heavy rainfall, are also an ideal location for the new sensor series. The precipitation is stored there temporarily and then released to the plant at a slower rate. If the basin cannot hold the accumulating quantities of water, part of the water is discharged. Due to legal requirements, such impounding events and discharged water quantities have to be measured and documented. Vegapuls C 22 stands out here due to its compact design and simple ceiling mounting, delivering the required measured values reliably – even in the event of flooding.

Controlling the cleaning processes

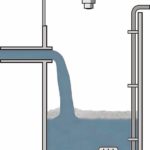

In the precleaning stage, floating materials are mechanically removed with rakes or sieves. This protects later process steps from buildup, clogging, and abrasion. Solids with diameters greater than 25 mm are trapped in the coarse screens, compressed in the screenings press, and then disposed.

The fine screen removes smaller residual materials from the waste water. Measurement of the water level difference between the front and the back of the screen is used to determine the degree of contamination and initiate the cleaning of the screen. This is where things get particularly rough and dirty. An ideal task for the fully encapsulated Vegapuls C 11. Reliable level measurement is also required in the containers where the solids, sand and sludge sorted out through coarse and fine raking are collected. Here, the measured values, which are also supplied by a Vegapuls C 11, give the signal to start the automatic exchange of the containers.

Through the addition of chemicals, phosphates in the wastewater are precipitated out in primary sedimentation, in aeration systems or in special precipitation and post-clarification pools. Precipitants like ferric chloride bind the phosphate chemically and deposit it in the sludge. In each chemical storage tank, a level measuring system as well as a limit level detector are deployed for continuous inventory monitoring and optimal dosing. Vegapuls C 21 is also used here. The sensors are approved as overfill protection systems according to WHG (Water Resources Act in Germany) and thus reliably protect the environment from an overfilling of the tanks.

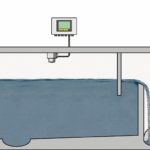

Displaying the essential readings

The sensors are supplemented by Vegamet controllers. These supply the connected 4…20 mA sensors, process the measured values and display them, all without complicated programming. A large display for data visualisation is integrated in the housing designed for harsh field conditions. Vegamet enables simple implementation of pump controls, flow measurement in open channels/weirs and totalising counters as well as the calculation of difference, total and average values. Limit values can be monitored and relays switched, e.g. for overfill protection according to WHG.

The compact Vegapuls series is ideally suited for a wide range of applications in the waste water industry. It is a real alternative to ultrasonic sensors not only because of its low price, but also because of its high reliability and long service life. All sensors and controllers can also be adjusted via a smartphone or tablet with Bluetooth functionality. This makes everyday work easier in the harsh environments of the industry – especially since many sensors are often located in virtually inaccessible places.

Vega Grieshaber KG, Schiltach, Germany