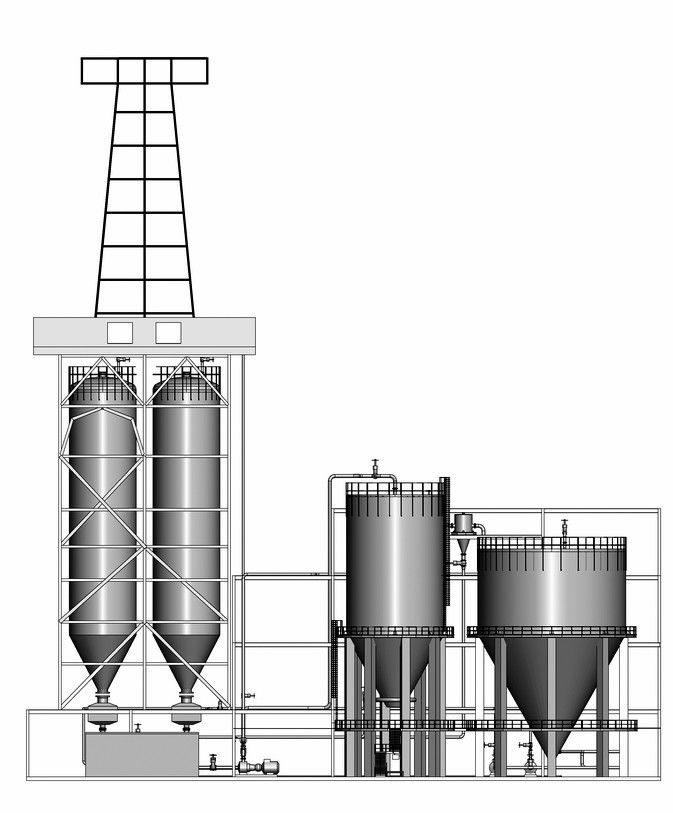

The Polish group Lotos put the new delayed coker complex of the refinery in Gdansk, Poland, into operation at the end of 2019 and thus reached a milestone in the EFRA project. The heart of the complex is the delayed coking unit (DCU), in which the closed coke slurry system (CCSS) process developed by Triplan has been integrated.

The closed, space-saving CCSS system, which enables almost emission-free discharge, processing and transportation of coke, avoids environmental influences of conventional processes, such as the particle and pollutant emissions from open pit/pad systems. Further advantages are the efficient dewatering of the coke and resource-conserving water management, which is characterised by lower water consumption and effective treatment. In addition, the CCSS does not incur any higher investment costs and the opera-tion costs are reduced thanks to the high degree of automation.

With the construction of the DCU in the refinery complex, the operator can process the heavy residues from the processing of crude oil into high-quality diesel oil, aviation fuel and petroleum coke, thereby not only protecting the environment, but also increasing the refinery margins.

TTP GmbH, Rosenheim, Germany