Germany’s Regulation on Health and Safety in the Use of Work Equipment requires pressure vessels, piping and other pressurised plant components to be inspected periodically for aspects such as tightness, cracking and/or possible spread of corrosion. This is commonly done by internal inspection including visual exami-nation or hydrostatic test. However, this type of inspection can be time- and cost-

intensive; vessels need to be drained and cleaned, which involves measures in occupational health and safety (OH&S), as well as environmental protection and the costs

of production loss due to shutdown of the system.

In-service testing

Acoustic emission testing (AT) can replace internal inspection of pressure vessels and serve as a monitoring tool during strength testing, also for OH&S. Under certain conditions, pressure vessels can be tested in service as well as by means of continuous monitoring. Depending on the mode of operation, the exclusion of some damage mechanisms and the on-site conditions, draining and cleaning of the pressure vessels may not be necessary. In other words, the time and costs associated with these activities can be saved. However, pressure application during testing is one of the prerequisites for AT. The test pressure PTAT should be set to at least 1.1 times the maximum pressure during operation POP..

Triggering sound waves

AT is a non-destructive test method (NDT) that allows integrated detection and localisation of leakage and discontinuities. Application of the test pressure triggers changes in the structure of the metal, such as local plastic deformations or crack propagation. Acoustic emissions are generated by sudden mechanical motions in the material structure, which cause vibrations in their surroundings. The surrounding structure deforms elastically and bounces back, causing a transient elastic sound wave which propagates from its point of origin. The sound waves are absorbed by piezoelectric sensors. The signals are recorded and processed to detect and localise the acoustic emission (AE) sources. With only a few sensors at fixed positions, experts can perform 100 % testing and monitoring of a structure. Even large vessels and components with complex geometries or difficult-to-access areas and fittings can be tested easily and reliably.

The sensitive measurement method “listens” to the material, recording discontinuities as they arise or propagate. Given this, the test method offers real-time capability and can also be used as an OH&S action for monitoring gas-pressure tests. Using AT, impending failure of the test object will be displayed at an early stage. This allows the test process to be safely interrupted or terminated at any time.

Classification of AE sources

The signals are grouped into clusters based on their local accumulations. The number of signals detected in a single cluster indicates the degree of activity at that point. Categorising the signals and clusters into three classes by their AE activity and intensity has proved to be helpful in the evaluation of measurement results:

- Class 1 – insignificant source, no actions required

- Class 2 – active source, visual examination or other NDT method for follow-up inspection and evaluation

- Class 3 – highly active source, interruption/termination of testing, pressure relief, visual examination and other NDT methods for follow-up inspection and evaluation before operation of the pressure equipment is restarted

This provides a good basis for planning and implementing the next steps and possible actions to be taken. As a matter of principle, the plant manager and the organisation commissioned to carry out the test should agree on the quantitative evaluation criteria and the actions derived therefrom before measurement is performed, and document them in a test instruction.

AT of a large vessel

A refinery manager commissioned TÜV SÜD to perform acoustic emission testing of a C4 column. AT should replace visual exami-nation of the inside walls of a large vessel in internal inspection without process interruption. The industrial-sized vessel, manufactured in 2006 from fine-grain structural steel (P355 NH), had the following dimensions: height 74.3 m, diameter 4.44 m, volume 1,160 m3 and wall thickness 22 to 26 mm. The inside structure of the vessel was complex, with several features and valve trays.

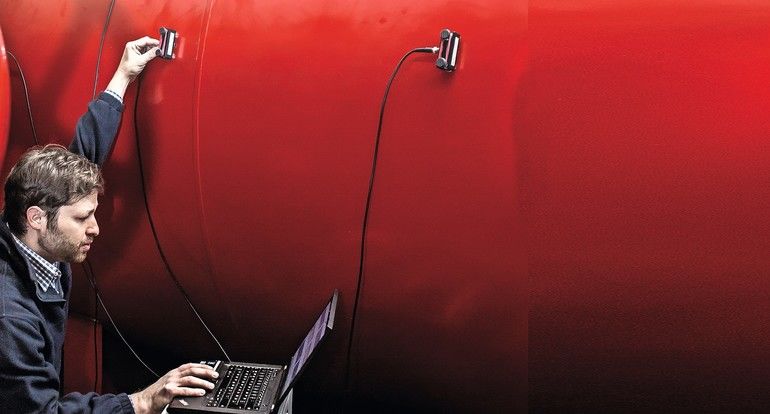

Before AT could be carried out, certain preparations had to be made. For example, the column first had to be scaffolded to grant access for the installation of the 88 piezoelectric sensors across the outside wall of the vessel according to the layout plan. To install the sensors to the blank metal surface of the pressure vessel with the help of magnetic holders and a couplant, the insulation of the column first had to be locally removed over an area of 20 x 20 cm at each sensor location.

The test pressure (PTAT = 1.1 x POP) was applied from the plant manager’s control centre. Vessel testing was performed over a period of 12 hours as online monitoring in real time. Result: Testing showed active class 2 AE sources in some areas. TÜV SÜD recommended carrying out follow-up inspection of these zones in the form of classic weld testing and surface inspection using UT phased array technology.

TÜV SÜD Chemie Service GmbH, Frankfurt am Main

Author: Klaus Michael Fischer

Innovation Manager & Technical Director for Fire and Explosion Prevention,

TÜV SÜD Chemie Service

Acoustic Emissions Testing: Standards

Acoustic emissions testing (AT) of pressure equipment must comply with specific national or European standards. The general approach is described in EN 13554. The harmonised EN 14584 standard governs the test method for metallic pres-sure equipment using proof testing with planar location of AE sources. Under EN ISO 9712, testing must be performed by qualified and certified personnel. The instruments used must comply with the requirements of EN 13477–2 and undergo regular verification according to this standard.