If problems occur in a cooling water circuit, they often affect the heat exchanger first. Deposits form there as a result of solid matter and microorganisms in the water, eventually leading to blockage. Krone’s multi-stage filtration systems not only prevent this reliably, they also benefit the plant with a longer service life and reduced maintenance costs.

Alexander Matosovic

Membrane filtration systems are one option for separating solid matter. Modern spiral coil or capillary hollow-fibre modules combine maximum a membrane surface with a minimal space requirement. The disadvantage of these modules is that the gaps between the individual filter surfaces are very small. The dimensions of such tiny free cross-sections necessitate a near-optimal filter mesh size of between 40 and 150 µm for pre-treating the feed water. At the same time, large populations of microorganisms are more and more frequently encountered in the natural water of European water courses. They represent a serious threat to downstream systems, as they are capable of surviving in very hostile conditions. For the owner of a membrane filtration plant, this means that very small mesh sizes must be installed for a comparatively high particle load. The illusion that this can be achieved effectively and reliably with a single filtration stage tends to quickly disappear in practice.

Multi-stage filtration

In many cases, therefore, it is better to opt for multi-stage, automatic filtration. The higher acquisition costs are usually justified by the improved availability and lower maintenance costs, and recovered after running the system for only a short time.

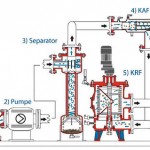

After analysing the water and the particle distribution, the required components can be selected. The scale of the system is dependent on the properties of the water on the one hand and on the hydraulic system and the conditions on site on the other (e.g. if an additional pump or a sludge separator is used).

The number of stages is likewise determined on the basis of the water properties as well as by extensive tests conducted in the field. The most important stages in a filtration system are firstly a centrifugal separator (recommended if there is a high sludge content) and a self-cleaning filter that removes contaminants according to the Bernoulli principle. This is the pre-filtration stage with a mesh size of 100 to 200 µm. The second stage is implemented with an automatic backflush filter that achieves qualities of 120 to 40 µm (occasionally even up to 25 µm). Owing to the advantages the filter in the first stage provides for the process, the quality of the water for the finer filter downstream is improved to the extent that it can operate reliably and without interruption for a long period of time.

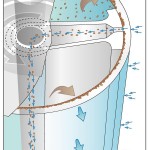

The fine filtration stage makes use of a simple cleaning principle: the medium flows through the filter sieve from the inside to the outside during the filtration process and solid particles are deposited on the inside. If the sieve is fouled, a cleaning cycle is activated, either based on the differential pressure previously defined by the operator – usually in the range from 0.25 to 0.5 bar – or by an integrated time control function.

A backflush nozzle, driven by a gear motor, withdraws the inside of the filter insert or the dirty side of the filter. A pressure gradient is created by a simultaneously opening, electropneumatic dirt drain valve in the flush line. This results in the forced discharge of the dirt on the sieve’s dirty side, because the flow is reversed in the vicinity of the backflush nozzle and the impurities are removed through the nozzle gap.

The distances between the nozzle and the filter material play an important role here. The smaller the gap, the greater the flushing effect. Fine filtration efficiencies of 25 to 50 µm require a very small nozzle gap, which in turn necessitates effective pre-filtration. This is achieved practically and reliably with multi-stage systems.

Hall 5.0, Booth G25

Online-Info www.cav.de/2209432

Share: