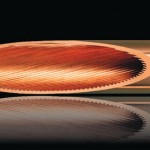

In order to increase the efficiency of heat exchangers in process engineering and reduce their size, the manufacturing trend is towards inner-grooved tubes and smaller tube diameters. Inner-grooved cuprofin tubes can be produced in series with a minimum diameter of 5 mm.

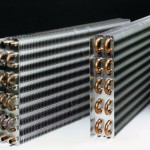

On the basis of copper, cupro-nickel and stainless steel, Wieland offers a wide range of high-quality tubes with larger inside surfaces for better heat transfer. These optimised surfaces ensure a high level of energy efficiency. Cuprofin tubes are used for both evaporation and condensation of refrigerants. In addition, they are suitable for transporting heat transfer fluids, e.g. in air-source heat exchangers. Efficiency is further improved through compact geometries tailored to the specific application. Inner-grooved tubes are developed in collaboration with the customer and continuously optimised at the in-house test laboratory. Depending on the process requirements, the user defines the best suited tube material.

Besides copper, the classic material, cupro-nickel and stainless steel are also used to manufacture cuprofin tubes. Tubes made of cupro-nickel are characterised by high corrosion resistance to saline atmosphere, especially in seawater applications, whereas stainless steel tubes are suitable for aggressive media or refrigerants such as ammonia. The cuprofin G tube was developed to enhance the heat transfer of water-glycol mixtures.

Tested in the laboratory

Wieland combines proven manufacturing technology with thermal engineering development. At its in-house laboratories, experts carry out pilot-scale tests based on the customer’s operating or production conditions. Special test facilities available in the heat transfer laboratory are used to determine the efficiency of individual components or assemblies. On specially designed test rigs, it is possible to measure inner-grooved tubes under evaporation and condensation conditions – important processes in air conditioning and refrigeration – using almost any safety refrigerant such as R134a, R410A, R407A and R404A.

Tests of heat generation and heat storage can be carried out for heating engineering applications. A test rig for gas-fired boilers facilitates precise measurements of performance and combustion. Free convection flow can be observed on a rig for heat exchangers in hot water tanks. This provides the basis for optimising finned tubes and heat exchangers intended for use with conventional and renewable energy sources. In close cooperation with universities and research institutes worldwide, Wieland is also engaged in R&D activities related to enhanced heat transfer on behalf of the hydrocarbon processing industry.

Online-Info www.cpp-net.com/2210426

Share: