Today’s technology offers compressed air users many ways to significantly reduce energy consumption and minimise CO2 output. Unsurprisingly, forward-looking solutions and innovative products play a key role. Compressed air users would be able to tap into the average 33 % efficiency potential identified back in 2000 far more effectively if they systematically implemented all available savings measures.

The authors: Erwin Ruppelt Senior Project Engineer, Kaeser Kompressoren Michael Bahr Press Officer, Kaeser Kompressoren

A study carried out within the framework of the Save II initiative determined that, on average, compressed air systems in Europe had an energy saving potential of nearly 33 %. Kaeser Kompressoren’s expertise as a leading compressed air systems provider also proved invaluable for the subsequent “Druckluft effizient” (Efficient Compressed Air) measurement campaign. The resulting audits revealed potential energy savings of between 18 and 70 % for the enterprises assessed, depending on their circumstances. In spite of various improvements, in other words, many companies’ compressed air installations are more akin to those of the 1970s than to today’s energy efficient systems. To bring about the desired changes, therefore, new technological developments have an important role to play when it comes to increasing the efficiency of compressed air systems as a whole. In order to achieve the best possible results, detailed optimisation is required on the one hand and improved matching of the compressed air system components on the other.

Drives with enhanced performance

In the last few years it has been possible to develop electric motors that operate at unprecedented levels of efficiency. In order to harmonise the various energy efficiency regulations for asynchronous motors from around the world in a unified standard, the International Electrotechnical Commission (IEC) created IEC 60034–30, which defines efficiency classes IE1 to IE3, where IE3 is the highest class. In Europe, motors complying with this premium efficiency class will be obligatory for drives from 7.5 to 375 kW as of January 1, 2015. Kaeser already started installing IE3 motors in its new rotary screw compressors in 2010, however, and the rest of the product range will follow suit in a gradual roll-out.

Modern compressors are prime examples of highly developed mechatronic systems. Their efficiency is consequently determined by the optimal interplay not only between mechan-ical and thermodynamic devices but also between electrical and electronic components. Power transmission, too, plays a key role: modern direct drive systems eliminate the transmission losses associated with gear or belt driven systems, as the drive motor and compressor air end rotate at exactly the same speed. The energy efficiency of the air end itself can also be increased further by optimising the screw rotor profile and ancillary equipment for cooling as well as by minimising internal pres-sure losses.

Flexible internal compressor control

A further important efficiency enhancing component is the compressor’s internal controller. In days gone by, these systems often only had one control mode, yet modern industrial PC-based systems offer up to five pre-programmed options, enabling compressor performance to be precisely adapted to suit compressed air demand. The Sigma Control 2 controller offers added advantages: this advanced system provides greater flexibility through its numerous interfaces and innovative plug-in communication modules. As a result, connection to energy-saving master control systems, computer networks and/or remote diagnostics and monitoring systems couldn’t be easier. The large display also simplifies on-site communication with the system, whilst the connection of an RFID reader ensures service continuity, increases security and significantly raises service quality.

These controllers moreover provide an excellent basis for predictive, preventive mainte-nance resulting from continuous monitoring of the compressor status and the compressed air filters. This is of course essential for any comprehensive service concept that strives to ensure maximum dependability and availability as well as optimised energy and maintenance costs. Needless to say, such concepts should not be restricted solely to the compressors and other components but extended to cover the compressed air system as a whole.

Energy efficient compressed air drying

The impact of air drying on the energy efficiency of a compressed air system should likewise not be underestimated. Significant strides have been made in recent years regarding the most efficient and widely used process for refrigeration drying (for pressure dew points to +3 °C). New refrigerants and advanced refrigeration dryers equipped with energy saving cycling control and the ability to adapt to actual compressed air demand have led to significant energy savings. There is now also a highly efficient combination process involving refrigeration and desiccant drying that is designed for applications requiring considerably dryer air (pressure dew points to -40 °C). In some instances, this method can completely replace the far more energy intensive process of desiccant drying while in others, it is even possible to use recyclable heat from the compressor to regenerate the desiccant material.

Compressed air demand analysis

Although it is obviously essential to maximise the efficiency of the individual components in a compressed air installation, this requirement is not in itself sufficient to ensure one hundred percent efficiency of the system as a whole. The key to success lies in the optimal integration of these separate components into the system. This is where computer-aided demand analyses such as Kaeser’s ADA (air demand analysis) prove invaluable: with their help, it is pos-sible to determine the actual compressed air demand over time, establish the efficiency of a compressed air system and identify ways to improve availability and performance.

Special planning software such as Kess energy saving system, for example, can subsequently simulate and compare various alternative systems and accurately calculate the potential energy savings.

Compressed air management and more

There are also many options for potential economies when it comes to monitoring and control of the compressed air system. Advanced master control and management systems, such as Sigma air manager (SAM), provide users with the transparency and performance required to tap into these savings. Featuring state-of-the-art adaptive 3D control technology, the latest SAM versions are now more effective than ever. What sets these next generation control solutions apart from conventional systems is that they are able to consider the three crucial dimensions that determine energy-efficient compressor control in a compressed air station, namely:

- Switching losses associated with compressor start-up and shut-down

- Additional energy consumption for pres-sure increases above the required pressure

- Control losses resulting from idling as well as FC losses

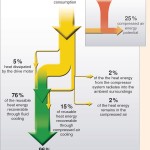

SAM constantly analyses the relationship between these factors, calculates the best pos-sible result and controls the compressors accordingly. Moreover, SAM delivers exceptional cost transparency and coordinates preventative maintenance for the entire compressed air system. Heat recovery represents another major source of potential energy savings: up to 96 % of the energy fed into a compressor can be recovered and reused for heating purposes. Companies that factor this energy into their supply concept can consequently benefit from substantial additional cost reductions and mitigate their impact on the environment through lower CO2 emissions.

The energy losses incurred as a result of leakages in the compressed air distribution piping should also not be overlooked: leakage rates of 10 to 25% are common. With help from modern detection equipment however, leakages can be quickly located and rectified. Other causes of energy losses and large pressure differences in the compressed air distribution network include contamination in the piping, inadequate pipe diameters and an unfavourable pipe layout that adversely affects flow performance. These shortcomings should therefore likewise be corrected or avoided.

Hall 26, Booth D42

Online-Info: www.cpp-net.com/2111427

Share: