Plant manufacturers on one hand and the later plant operator (manufacturer) on the other have various duties and must comply with the legal requirements. Each party has to fulfil their legal obligations, of which some are overlapping. As an example, the plant manufacturer side has to comply with the following regulations: Conformity processes like the risk analysis according machine directive and SIL (Safety Integrity Level), environmental regulations like the TA Luft or WHG and risk analysis according hygiene and infection protection. The delivered documentation and operating manual and instructions has to comply with these legal requirements.

Glatt Ingenieurtechnik (GIT) operates a modern technology center for the product development, functionalization and manufacturing of powders, granules and pellets in Weimar. This allows GIT to continuously develop present requirements of all stakeholder further. In the technology center the customers manufacturing process can be developed, tested and optimized prior to engineering of the plant. Furthermore GIT can act as a certified toll manufacturer for industrial customers – plant operator and manufacturer.

Experience as an added value for the customers

The insights and experience of a practical technology approach are not only valuable for the plant manufacturer, but also for the customer who is the later manufacturer. The customer can participate from this long term experience. From optimized layout concepts all the way to complete civil solutions, GIT can also contribute to waste and environmental management, energy and sustainability concepts as well as safe handling and containment solutions for toxic and high potent drugs and substances. Even product safety has to be incorporated from the beginning. Here maximum product safety of foods as well as for products directly manufactured for the consumer market is paramount.

For the manufacturer this is a very sensitive issue, since in case of a liability incident (accident/claim/damage), the product liability can not be excluded. As an example, the present Food Safety System Certification 22000 (FSSC) of the Global Food Safety Initiative (GFSI) requires food manufacturers to validate their manufacturing process with respect to the hygienic situation in the production areas, avoidance of physical and microbiological contamination, as well as avoidance of fraud of foods. At this point it becomes essential to establish with expertise and a sense of proportion not only a solid manufacturing processes in the plant, but a high quality state of the art overall manucaturing process.

Hygienic design on default, rather than as a duty

One of the most sustainable measures for hygiene and product safety is the consistent hygienic design of systems. Manufacturers should not only focus on the application of hygienic design principles and and corresponding supplier certifications. In an extensive GIT project, for example, the CIP capability of batch fluidised bed systems was intensively investigated and a test facility was built specifically for this purpose.

Design modifications were tested and evaluated in situ. The EHEDG membership for hygienic design and involvement in the creation of EHEDG guidelines for components and machines for many years guarantee the permanent development of know-how as well as further training and exchange on the latest issues. This knowledge base is passed on in dialogue with the customer and translated into concrete plant and product hygiene. From the consulting and participation in the interface analysis or the Hazard and Operability Study (HAZOP) on production plants in combination with the company‘s own experience, new approaches are also being developed for concepts for dust-free and contamination-free handling of highly active toxic products or to improve occupational safety during cleaning and maintenance work on fluidised and fluidised bed systems.

Occupational safety taken into account, eliminating residual risks

One example is the cleaning intervals of spray nozzles. This mainly depends on the product and is indicated by deviations in particle composition. The nozzle’s inner tube is usually removed as follows: the operator first terminates the air spray at the contaminated nozzle and checks whether the safety gear (consisting of safety ropes or chains) is attached. Only then may the connecting clamp be opened and the inner tube — with the liquid insert — pulled out of the spray lance. If the inner tube is loosened during the process without interrupting the spray gas supply and without attaching the safety gear, the inner tube will shoot out abruptly owing to pressure … or cause an explosion.

If the spray unit is at head height, which is typical with larger systems, there is a danger to life. An advanced spray nozzle safety device secures the inner pipe using a lock-and-key principle to prevent explosions and ensure that any potential operating error during nozzle disassembly has no adverse health consequences. The design of the solution consists of protected recesses and catch pins. Both elements completely eliminate risks such as the uncontrolled ejection of the inner tube. A welcome side-effect is that there is no need to clean and replace the safety chains. The explosion-proof hygienic nozzle can also be retrofitted. This is the result of many years of practical operating experience and regular risk analyses in which the status quo was scrutinised from the operator’s point of view.

Explosion protection: the safe way to bulk goods

Customers need to be able to rely on the expertise of their plant manufacturer, especially when it comes to safety. Various concepts are available for explosion protection; these should be both assessed and safeguarded by calculation, and also (ideally) confirmed in practical explosion tests. To ensure maximum plant operator safety, ignition sources should be avoided as much as possible, all machine parts should be earthed and an appropriate plant design should have been selected.

The customer can select the best concept for their needs. For example, designing a system to be pressure-resistant to 12 bar as an alternative to explosion suppression or pressure relief is eminently possible with round designs. Particularly in the case of gas explosion protection or hybrid mixtures, the investment costs can be significantly lower if you can manage without an elaborate circular gas system. However, if solvents are present in the exhaust air, gas purification by combustion or scrubbing is required.

Systems that cannot be designed and built to be pressure-resistant, such as rectangular fluidised and spouted bed systems, must be protected by either an explosion suppression system or, alternatively, an inert circulating gas (nitrogen) system. Inertisation not only provides explosion and fire protection, but can also offer additional benefits for oxygen-sensitive products. Unsaturated oils, beta-carotenes or reactive chemical substances are protected from oxidation and show better long-term stability. The advantage here is that continuous operation is possible and the solvent can be recovered. However, the investment and operating costs are higher than for fresh/exhaust air operation.

It is also possible to operate the fluidised bed under vacuum. This reduces the oxygen content below the critical limit and sensitive products are also better protected against oxidation. The boiling point is reduced by the vacuum, which enables the operator to use lower process temperatures and saves heating power and operating costs. The solvent can also be recovered.

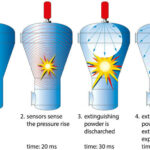

This solution is only structurally possible with round and batch systems and the choice of solvents is limited. Another option is explosion suppression; an extinguishing agent is sprayed into the reaction chamber in the event of a pressure increase. The disadvantage is that, once triggered, the extinguishing agent cartridges have to be replaced and production is interrupted.

There are many options for application-orientated explosion protection, but the following applies to every process: it must be tailored as closely as possible to the requirements of the operator and not to the preferences of the supplier. If the plant manufacturer thinks outside the box in the interests of the customer and helps the operator to better fulfil their obligations, both sides benefit. The upshot? Profitability, process quality and safety during the production of bulk solids from the outset.

Glatt Ingenieurtechnik GmbH, Weimar

Authors:

Frank Ohlendorf

Head of Business Support

Gerald Beck

Senior Project Manager

Sören Albers

Head of Contract Manufacturing

Glatt Ingenieurtechnik, Division Process Technology Food, Feed & Fine Chemicals