Traditionally, many polymerisation reactions in polymer production are carried out batchwise, for example in solution, emulsion or in a melt. This procedure reaches its limits if, for example, the reaction is very exothermic or the viscosity increases considerably during the course of the reaction. Innovative technologies are then required. This is where the planetary roller reactor (PRR) based on the planetary roller system offers a solution.

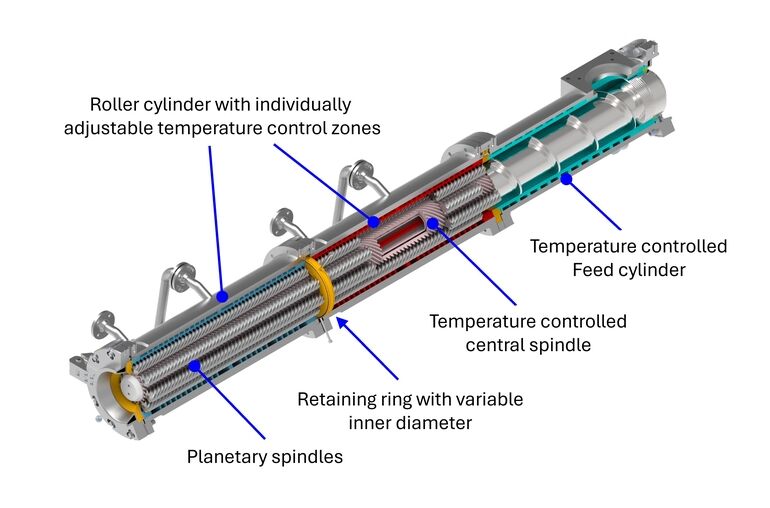

The PRR is a multi-modular extrusion system characterized by targeted mechanical adaptability and precise thermal process control. In conjunction with the special mechanical working principle of this machine type, this enables the realization of sophisticated mixing, degassing and reactive extrusion processes, which are used in the manufacture of a wide spectrum of products and often form the basis for new material innovations.

The PRR offers process engineering advantages for the preparation and further chemical conversion of raw polymerisate. With the help of the process-orientated, adaptable process technology, a wide range of possibilities can be presented to modify the properties of materials through chemical reactions. In many cases, these can be realized in a continuous production process and therefore cost-efficiently and with a stable process quality.

Advantages of the PRR

The PRR can mix, homogenize, degas and gently remove volatile components even from highly viscous extrudates. This system can serve as a continuous reactor for chemical reactions, particularly in the area of highly viscous thermoplastic melts. The PRR offers various advantages not only compared to traditional batch reaction control, but also compared to other processing methods.

These advantages include:

- High and widely scalable throughput from a few kilograms to more than ten tons per hour, depending on the design size

- Greater process safety due to relatively low total amount of reactive components in the process

- High and reproducible product quality thanks to precisely controllable reaction conditions, e.g. precise temperature and pressure profiles

- Less emissions thanks to very efficient degassing of gases and vapours as well as volatile degradation products

- Compared to stirred vessel reactors or conventional processing aggregates, lower specific energy requirement for temperature control and drive

Greatest possible flexibility

Another advantage, especially in comparison to conventional single-screw or twin-screw extruders, is that the PRR can still be operated without any problems even when it is only filled to around 10 %. This gives the operator the greatest possible flexibility when adjusting capacity.

For the modification of different substances, i.e. chemical conversion, the extruder can be continuously supplied with recipe-related amounts of various solids and liquids in different process and temperature control zones. The residence time in the individual process zones of the process section can be controlled mechanically.

This allows that even higher viscosity materials can be added into the ongoing process with good mixing quality. It is also possible to react chemicals under pressure or to induce, control and interrupt reactions in individual process zones in a planned manner. A chemical reaction can also extend over several process zones and run through different pressure and temperature conditions, which specifically influence the course of the reaction.

The modular design of the PRR modular system allows chemical processes to be specifically customised. The mechanically controllable process zones and individual temperature control zones enable targeted and efficient control in the individual phases of reaction processes, allowing certain sequences of physical and chemical process steps to run one after the other in a continuous process. br

Entex Rust & Mitschke

Achema: Hall 4.0, Stand B43