Plastic random packings are widely used in scrubbers for exhaust air purification, operating on the principles of absorption and desorption. However, they are often outperformed by structured packings. To showcase their effectiveness, Brentwood’s structured packings, such as the Massdek 250 HTC, were tested in a pilot plant. The test series included various types of packings to compare their performance.

For applications requiring high levels of cleanliness and systems that are not prone to clogging, counterflow absorbers with packed beds remain the preferred engineering solution. Packed beds have a long-standing history, starting with the initial use of random packings made from ceramic rings. Over time, these have evolved into what we now know as structured packings. Continuous product development has transformed structured packings into highly efficient tools, consistently improving and optimizing the performance of traditional random packings.

Historically, structured packings have primarily been used in distillation and rectification processes. Due to the nature of these processes, involving specific input materials and temperatures, metal sheet and metal wire gauze packing have been the main types utilized.

Plastic structured packings

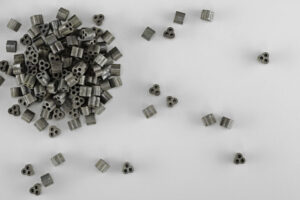

On the other hand, plastic structured packings are the optimal choice for absorption and desorption processes, especially high-performance types with vertical inlet and outlet channels. Their high-capacity design, featuring various channel inclinations and substructures, ensures they are ideally matched to the specific requirements of the process.

Brentwood supplies various types of Massdek packings made from thermoplastics for these applications. Massdek 250 HTC, a high-performance packing, provides significantly better separation performance than a 25 mm random packing and significantly less pressure drop than a 50 mm random packing. This was confirmed experimentally by a study conducted by a third-party test agency.

Third-party test rig Oberhausen

In accordance with the AbsoDeso standards, the third-party agency tested the hydraulic and separation properties of the structured packings with a diameter of 600 mm in a test facility: The test plant‘s packing bed was 2135 mm high and consisted of seven layers. During the tests, the dry and sprinkled pressure loss and the dynamic hold-up were determined hydraulically.

The separation test was carried out using the NaOH/CO2 system to determine the effective mass transfer area and the mass transfer coefficient and with the NH3/H2SO4 system to determine the gas-side mass transfer coefficient βV on the gas side.

The tests and evaluations were based on the methods and recommendations developed in the AIF project 17116 N/1 „Standardization of mass transfer measurements during absorption/desorption“. The values determined in the test facility for the Massdek 250 HTC packing type can be compared with high-performance packings with a 45° channel inclination angle and with a 25 mm Pall ring made of PP.

The measured values were clear: the pressure loss of the packing type was reduced by 40% compared to packings with a 45° channel inclination angle and the same specific surface area, while the gas throughput capacity was increased by 15%. Compared to the 25 mm Pall Ring, the dry pressure drop of the new packing was only 10% of the packing. In an application with an Fv factor of 3.0 Pa0.5 and an irrigation density of 20 m3/(m²h), the specific pressure drop for the water-air system was only 1.25 mbar/m, which corresponds to the hydraulic properties of a 50 mm random grid packing. The separation performance was also seen to be around 20% better than that of a 25 mm pall ring.

Small areas with high performance

The tests confirmed existing research results: The effective surface area is only influenced to a small extent by the angle of inclination of the channels [(Tsai, 2011) and (Mackowiak, 1999)]. Consequently, the liquid-side mass transfer coefficient is comparably high to that of the Massdek 250 HTE. As expected, the gas-side mass transfer coefficient at an inclination angle of 60° is slightly lower than at 45°, but still high. This makes the high-performance packing Massdek 250 HTC particularly suitable for chemical scrubbing with the aim of maximum cleaning performance or when measures are required to increase separation performance and/or throughput.

In terms of separation performance and pressure drop, high-performance structured packings outperform all random packings with comparable specificity. These results significantly influence plant engineering.

The enhanced performance of Massdek 250 HTC allows for the use of smaller equipment in newly planned systems. Its significantly reduced pressure drop also helps lower overall operating costs and its low gas-side pressure drop proves retrofitting existing systems from random packings to Massdek structured packings cost-effective in a short period of time. br

Brentwood

Achema: Hall 4.0, Stand C46