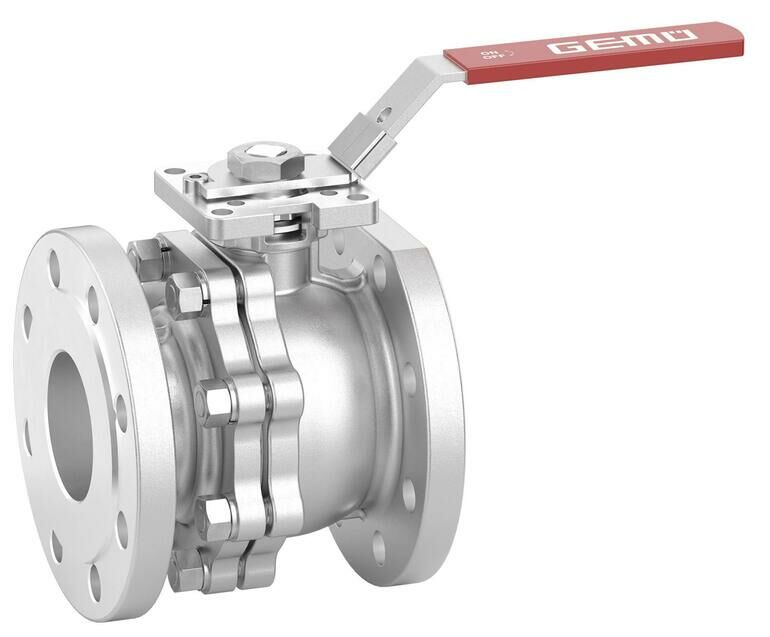

The ball valves in the BB0F series cover a wide range of applications in the chemical industry thanks to their configuration and the available construction and actuator versions. In the standard BB0F version, the media-wetted seat seals are made of PTFE with glass-fiber reinforcement (reinforced PTFE). This is what gives them exceptionally high material resistance when exposed to changing media and ensures a high level of safety when using dangerous media. The stainless-steel ball valves are suitable for use in applications at temperatures between -40 and +220 °C. Thanks to its two-piece body, the ball valve has only one connection point, guaranteeing reliable tightness. The ball valve has a fire-safe design as standard in accordance with API 607 and DIN EN ISO 10497, with the housing and shaft seal made of graphite. In areas of application where the risk for potential fires is high, a fire-safe valve, such as one of the BB0F options, is a suitable choice. The ball valve is available in nominal sizes DN 15 to DN 200 with flanged connections ANSI class 150 and PN40/PN16. Alongside applications in the chemical industry, this ball valve can also be used for heating systems and HVAC applications. The new BB0F series includes the B2F manualally operated ball valve, the B4F pneumatic ball valve and the B6F motorised version.

Gemü

Achema: Hall 8.0, Stand F4