Firmen im Artikel

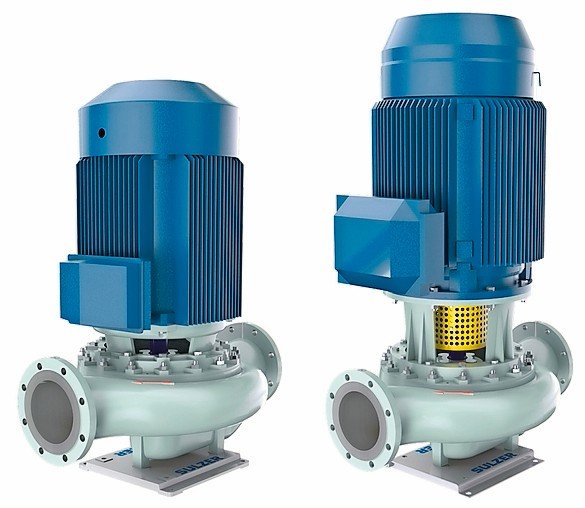

Sulzer developed the SIL pump range to meet the process requirements in various general and industrial applications. The SIL pump range is ideal for pumping mainly clean and slightly contaminated liquids, viscous liquids up to 2.5×10-4 m2/s, and fibrous slurries up to a consistency of 1 %. The hydraulic design ensures efficient pumping with a low NPSHr (net positive suction head required) across the whole pump range. The inline design together with the monoblock construction makes the SIL pump compact, rigid and reliable. The pump is available either with an integrated motor or with a standard IEC motor, and is easy and fast to install both in vertical and in horizontal positions. The inline pump range fulfills the efficiency regulations across all industries as well as the design requirements of the ISO 5199 international standard. The entire pump range exceeds the MEI 0.4. The monoblock construction eliminates the need for a bearing unit. The optimised shaft sealing chamber and impeller balancing holes guarantee improved conditions for the shaft seal and maximise its life time. The impeller is designed in tandem with the casing and sealing chamber. If needed, the back pull-out design allows quick access for servicing without detaching the pump from the piping.

Online search: cpp0118sulzer