Rapid Prototyping, 3D printing and additive manufacturing are all terms commonly used to refer to a manufacturing process in which three-dimensional components are created by laying down successive layers of material from the bottom up. In powder-based 3D printing, each layer of the structure constitutes a thin cross-section of the final object and is generated according to data from 3D-CAD tools. The layers of the object are printed by applying an energy source, usually a laser, and thereby melting fine powders into the precise shapes detailed in each cross-section. After completing one layer, the laser returns to the starting position and melts the newest layer together with the earlier ones, binding the structure. The final result is that the computer-generated 3D model is directly translated into a physical 3D object. Materials used in powder bed 3D printing include metals, plastics, ceramics, synthetic resins, carbon and graphite.

In particular, 3D printing is the method of choice when manufacturing products with complex geometric structures, small batches, and a high degree of customisation. 3D printing is also useful in the case of machine repair, especially to recreate complex parts that are no longer in production. Even the mechanical and technological aspects of the component can be replicated through 3D printing.

In comparison to more conventional machining and cutting processes, 3D printing does not involve a wide range of devices, castings, or product-specific tools. In many cases, significant savings can be made in terms of component volume and material loss. Furthermore, the process makes it possible to create complex structures that cannot be created via casting or machining. So, the economic efficiency of 3D printing rises in relation to increasing complexity and decreasing batch size.

Powder 3D printing process

Powder bed 3D printing proceeds succes-sively, layer by layer. For each layer of the structure, a powder bed is first laid to the desired thickness. Next, a precisely controlled energy source melts these clusters of powdery particles into the exact dimensions of the cross-section. Finally, surplus powders are removed, ideally to be repurposed for use in subsequent layers.

In order to achieve a functional end-product, the powders used in 3D printing must be adequately stable so that particle size, bulk density, and rheological characteristics remain unaffected by the melting process. At the same time, each step of the process must take place in quick succession if cost-efficiency is to be ensured. Speedy processing is usually aided by the implementation of pneumatic conveyance, which can often lead to a high degree of abrasion. For this reason, polymer powders used in 3D printing must be expertly conditioned.

This same challenge applies to selective laser micro sintering, a 3D manufacturing process that uses metallic powders. The metallic materials are laid into the powder bed by means of a doctor blade, a process that is often relatively time-intensive. The flowability characteristics of the materials play a decisive role in the resulting homogeneity of the powder bed. The powders must be as free-flowing as possible, requiring a spherical particle shape and a narrow particle size distribution. Additionally, agglomerates must be eliminated in order to prevent the formation of laminar or lineal defects in the finished component. Most metallic powders used in 3D printing are cohesive and have a particle size less than 10 µm, meaning they have a tendency to clump and adhere to the doctor blade or work surface. While this phenomenon is objectionable, it is also difficult to avoid.

In order to prevent the formation of unwanted agglomerates, 3D printing powders may be coated with nanoscopic additives as a means of conditioning them. Such a conditioning process is best performed in an automated precision mixer or fluidised bed processor, where clumping and unwanted agglomerates are less likely to form and the flowability characteristics of the powders can be improved.

3-in-1 mixer, dryer and reactor

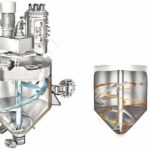

Mixing, drying, and reacting equipment, such as the Amixon’s conical mix-dryer type AMT, plays an important role in powder metallurgy and the preparation of polymers for 3D printing. These devices must be incredibly precise, because it is only possible to create a nanoscopic coating on each individual particle by adding the coating agent to the mixture in minute dosages as a weak solution or suspension.

Homogeneously integrating coating agents into bulk ingredients involves creating uniform levels of moisture within the powder. In order to achieve this, each and every individual particle must be wetted. If the liquid phase is ultimately to be dried, then the coating will remain evenly distributed upon the surface of each particle. Ideally the drying process will take place under a vacuum, reducing both duration and heat involved.

As a solution to this processing challenge, vertical mixing equipment that also doubles as a dryer and reactor can be used. A helical mixing blade rotates in the centre of the mixing chamber, generating a three-dimensional current that conveys its contents upwards along the periphery before they sink gravimetrically along the mixing shaft. This current envelopes the entire volume of the mixing chamber, making the process completely free of dead space.

Under these mixing conditions, only a low rotary frequency is necessary, reducing the amount of shear to which the particles are subjected. Every particle moves in relation to every other particle, flowing constantly and completely within the mixing vessel. The evaporation of liquid elements proceeds by gently warming the powders. Every contact-surface within the mixer is double-jacketed, from the walls to the arms of the helical mixing tool. Heated fluids (thermal oil, water or vapour) circulate below their surface.

Almost complete discharge

The ability to clearly separate each batch and avoid their intermixing is crucial for batch tracing and quality assurance. Amixon’s 3-in-1 conical mixer, dryer and reactor type AMT is exemplary in this regard. The conically shaped mixing vessel and convex helical blades facilitate the complete discharge of the mixer without segregation.

In some use cases, preparing powders for 3D printing requires the introduction and gentle homogenisation of trace amounts of extremely light flow additives, like pyrogenic silicon dioxide, to the mixture. Flow additives are only effective when mixed gently and homogeneously with bulk powders and cannot withstand any friction. The challenge lies in the fact that these light fractions have a bulk density of 150 g/dm³, a particle size of 10 µm, and a specific surface area of 350 m²/g, which explains their tendency to float to the surface of the powder mixture. This phenomenon is detrimental to the mixing process, as it can both slow down the operation and require a higher energy input, which may damage the delicate particle structures.

Special ceramic coatings

Special ceramic coatings are provided when the mixer or mixer dryer has to keep the powders free from any metal abrasion during mixing. The solutions are similar if the powders are particularly abrasive and the premature wear of the mixing tools has to be counteracted. Almost every processing machine that Amixon manufactures is a prototype – individual – partly in tiny but decisive nuances tailored to the requirements of the respective customer, in a wide variety of industries.

Amixon GmbH, Paderborn, Germany