The trigger for the development of the water-cooled system was an enquiry from two customers seeking a milling solution in order to achieve small particle sizes at a low temperature. Product tests and feasibility studies were first of all carried out at the factory. Completely diverse product requirements had to be satisfied by the same system: one client wanted to process a non-sensitive, free-flowing product while another needed to crush a sticky, natural product with a low fat content at low temperatures. Both products had to be milled to particle sizes between 50 (PSD D50) and 100 (PSD D90) microns. The various concepts, which were developed based on the initial results of the tests, as well as feasibility studies were subsequently presented to the clients and validated with them. Although the operating conditions were very different, both users opted for a Hammerwitt-6 using a closed water-cooled system: one customer was looking to integrate the system into an existing production line with lifting columns, product fixtures, product feeding, etc., whereas the other was planning to use a mobile system in multiple production rooms, for products with the most diverse properties. Frewitt concluded that the new system would above all have to be mobile and flexible, resulting in a system easily transferable from one production room to another, adapting to the existing physical plant without any major effort.

How does it work?

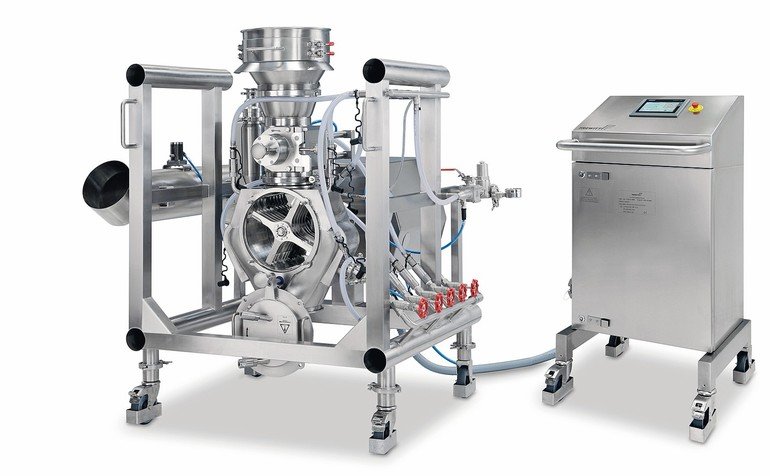

The product is fed to the hammer mill via an in-feed funnel, and subsequently milled in the water-cooled milling chamber to the specified particle size of between 50 and 100 microns at a temperature of approximately 15 °C. Thereafter, the product is conveyed from the outlet funnel to a filling system, where it is finally filled and weighed in an in-liner. The product temperature was well below the customer stipulated level in both applications.

The product remains in a closed system from feeding to filling and the temperature is monitored and controlled at all critical points of the water-cooled Hammerwitt. Due to this, the users’ entire cold storage rooms and other temporary storage areas, which were previously part of the process, have now been eliminated. The WIP concept and automatic filter dedusting and cleaning have enabled these customers to gain more time. Rooms previously reserved for product storage can instead be put to more efficient and profitable use.

The water-cooled system has opened up several new options for the Hammerwitt: not only can it be employed to fine-mill and pulverize hard, crystalline and fibrous products, but also temperature-sensitive ones.

Online search: cpp0118frewitt