As a supplier to almost all manufacturing companies, the chemical industry relies on efficient and safe processes to meet its production requirements. Since most chemical reactions are either exothermic and release heat, or endothermic and absorb heat, a reliable temperature control application plays a central role in the chemical industry.

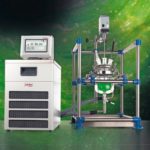

Julabo has developed the high-end circulators of the new Magio series with new future-oriented technologies, especially for such requirements. They are manufactured in Germany to the highest quality standards. Especially the refrigerated circulators of the Magio series offer the ideal conditions for precise external temperature control as required by the chemical industry, for example, in reactor temperature control.

Reactor temperature control

In both chemical and biological processes, the conversion of substances often takes place in reactors, which make it possible to create consistent conditions and a safe space for the reactions. This requires temperature control systems with fast and precise compensation and a wide temperature range. This is why temperature control systems such as the Magio circulators are used, which react dynamically to temperature changes inside the reactor and compensate for them quickly and reliably. The reactor type, its size and the material (e.g. glass or metal) as well as the wall thickness, and the thermal conductivity associated with the material are, among other things, decisive parameters. In addition to the process having to be temperature-controlled, these parameters also influence the choice of the temperature control system. Pump capacity, pressure build-up, heat exchange rates, and the efficiency of the components in the temperature control system must precisely cover the individual requirements to guarantee process reliability and effective material conversion. For special requirements outside the standard temperature control, specially-developed temperature control solutions are also considered. In most cases, however, this is not necessary because temperature control systems available on the market can be easily and efficiently adapted to individual requirements.

For temperatures from -50 to +300 °C

With the Magio series, Julabo offers products of the highest performance class with a working temperature range from -50 to +300 °C and a heating capacity of up to 3 kW. Due to the high heating and cooling capacity, the models guarantee short heat-up and cool-down times. In combination with the high-performance power pressure/suction pump with output values of up to 31 l/min or 0.92 bar (pressure) and -0.4 bar (suction), the Magio units are ideal for the most demanding external applications. The pump is not only powerful, but it is also continuously adjustable, making it easy to adapt to pressure or volume sensitive external applications. Furthermore, samples can also be temperature-controlled in the internal bath. To ensure maximum resistance to chemical substances, all parts in contact with the medium are made of stainless steel. The high-quality insulation of all relevant components supports energy efficiency during operation.

Functional operation

The high-resolution TFT touch display offers a multilingual user interface and stands for simple, intuitive operation and optimum visibility of relevant functions.

The modern display shows all important information at a glance. Three pre-defined, generous main screens clearly show data and graphics with different application focuses. The menu navigation is self-explanatory and arranged according to relevance in the daily work. All display functions can be operated at the touch of a finger. This allows even complex applications to be controlled easily and safely. The support function assists with further detailed questions at any time.

The sophisticated operating concept of the Magio series allows quick and convenient access to the most frequently used functions. All operating elements, as well as safety functions, can be easily operated from the front. The main switch on the top of the circulator simultaneously switches the circulator and refrigeration unit on and off. With the bright and extremely robust touch display, it is visible from afar and can be read easily even from a distance. The circulator fully controls the connected cooling unit during operation. Inclined pump connections on the back of the model facilitate the connection of external applications. Modern interfaces such as USB, RS 232, and Ethernet support a simple remote control.

Safety through automatic shut-off

For optimum process reliability, critical states are indicated visually and acoustically at an early stage. The automatic shut-off in the event of high temperature or low liquid level additionally provides maximum safety. Classification III according to DIN 12876-1 enables safe operation, even with flammable fluids. The fill level of the temperature control medium can be read at any time on the display.

The bath fluid is drained without special tools, comfortably and cleanly via the drain tap. The magnetic front grid of the refrigerated circulators can be removed easily for time-saving care and maintenance of the model.

As usual with Julabo, all Magio models do not have vent slots on the sides of the system. Thus, they can be placed directly next to other devices and applications or against walls to save space. Depending on the model, the refrigerated circulators from the Magio series have handles or castors for easy transport. In combination with the ergonomic handles, the models can be easily and comfortably moved to a different location.

Individual solutions

In chemical reaction and process engineering, a precise temperature control application has a decisive influence on production output, product quality, and process reliability. The requirements placed on temperature control systems are strongly application-related. Due to the extensive range of accessories, the wide temperature range, and the extraordinary dynamics, the circulators of the Magio series can be adapted modularly and individually to almost any application. Modern interfaces and an integrated programmer complete the intelligent design.

Julabo GmbH, Seelbach, Germany