With CPC couplings, hose assemblies in nominal diameters from 1.2 to 19 mm can be connected and disconnected easily, quickly and cleanly. Most of these couplings are available with shut-off valves on one or both ends and You have various connection options for the attachment of the couplings, depending on the medium and the tubes used. The couplings are made of different materials to cover all requirements regarding resistance to chemicals, pressures of up to 17 bar and temperatures from -40 to +140 °C. With multiple connector quick-release couplings, even two, six or ten tubes can be connected easily and without confusion. Wolftechnik, main distributor for CPC quick couplings in German-speaking regions, stores all common CPC quick coupling series for industrial applications.

Standard and high-flow couplings

SMC couplings are the smallest coupling series from CPC. These twist-to-connect couplings provide a reliable and more secure alternative to luer-type connections. The coupling design allows tubes to rotate freely when connected, preventing both kinking and accidental disconnection during use.

PMC series couplings are CPC’s most popular quick couplings. They are available in two types of materials. The standard version made in Delrin acetal is extremely durable and suitable for use with most mild chemicals. The PMC12 is made in polypropylene and is resistant to a wide range of chemicals.

The EFC series has an enlarged nominal diameter to increase the flow rate. Made of polypropylene, the series is predestined for use with acids and darkroom chemicals. For particularly high flows cater HFC quick couplings. Their main features are an optimised flow, ergonomic design and low weight. They are available in polypropylene, polysulfone and in a UV-resistant material. HFC couplings are recommended for all applications with water, acids, alkaline substances and most other chemicals.

The FFC35 series has been designed for extra high flow. The external design corresponds to that of the HFC series, while the inside features a much larger flow bore. The FFC quick couplings are thus only available as non-valved couplings and are made entirely from polysulfone. The series is widely used in cooling circuits and mobile devices with water supply connections.

Robust and non-spill CPC series

A stainless steel version has been added to the well-proven MC quick-release couplings made of chrome-plated brass and extends the range of applications. The couplings have a particularly long service life and are highly pressure and temperature resistant. They are used in applications with rugged conditions. The MC series is identical to the PMC series made of plastic.

The LC series is now also available in stainless steel. As with the MC series, the LC series was designed to increase the service life in harsh operating conditions. As a high-temperature version, the couplings can also be equipped with special valves and O-rings. In the new ranges of leak-free CPC quick couplings (non-spill quick couplings), the NS1 series is the smallest version and the NSH series the largest. It offers excellent throughput values. In between are the NS2 series, the NS4 series and the NS6 series. The special valve mechanism allows for dripfree disconnection. NS1 coupling bodies and plugs are made from glass-filled polypropylene and feature EPDM O-rings and stainless steel springs. The release latch is made from PEEK. This makes their use interesting for all applications in which dangerous chemicals are conveyed or where electronic components are located in the area of the tube connection.

The closed-system design of the LQ couplings provides drip-free tube connections with patented valve technology designed for frequent connect/disconnect. The redundant double sealing mechanism of the plug coupling remains drip-free even during long sealing times. LQ quick-release couplings enable shutdown in the event of pressure without any leakage. This makes them ultra-reliable for use in sensitive areas like liquid cooling applications in order to protect the electronics from the effects of liquids and to be able to change the clutches during operation.

Tube connectors, valves and filters

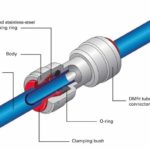

The push-fit connectors made from Delrin acetal for metric plastic tubes are available as standard tube connectors and also as connectors equipped with ball valves, needle valves, check valves and inline filters. Given the huge variety of connectors in L, Y, T and X shapes, the DM-fit series offers an impressive range of connecting options for plastic tubes with nominal diameters of 4 to 12 mm. In addition, the DMfit connectors are available as tube-to-tube couplings and adapters with female and male threads.

To connect the tube ends, simply push them into the connector port. The tube ends can at any time be disconnected. An O-ring between the tube and the outer part of the connector provides a reliable seal. The tube end is kept in its position by a barbed stainless steel retaining ring, preventing inadvertent disconnection. To open the connection, simply hold the stainless steel retaining ring by its outer plastic collar and pull the tube from the push-fit connector.

Fittings complete the programme

EJ fittings made of plastic cater for any type of connection between plastic tubes with nominal diameters of 1/16” to 3/4”. They are available in virgin PP, virgin PE and PVDF, and are certified for use in the foodstuff, medical technical and beverage industries. The fittings come in many shapes and sizes – from straight connectors, threaded pieces to elbows, tees and manifold pieces – allowing for virtually any tubing layout. Special reducers and adapter plugs enable you to connect tubes of various nominal dimensions.

TEF threaded fittings can be used for pipe threads in the nominal sizes from 1/8” to 1/2”. The TEF range includes reducers, elbows and tees, as well as simple double nipples, plugs and caps. The fittings are made from Nylon 66 and dyed blue. Thanks to the excellent thermal and mechanical properties of Nylon 66, TEF threaded fittings are suitable for operating temperatures of up to 120 °C and maximum operating pressures of 14 bar.

Wolftechnik Filtersysteme GmbH & Co. KG, Weil der Stadt