Pharmaceutical companies faced with numerous national and international standards need equipment that meets the strictest hygiene and clean room specifications. In applications of this kind, the automation components must literally offer a clean solution. One industrial workstation now in use at the Schering pharmaceuticals group combines a desk, PC tower and monitor housing in a stainless steel enclosure.

Stefan Körner and Sascha Preußner-Pfaff

In order to ensure maximum product quality in the sensitive pharmaceuticals sector, Rittal has especially optimised part of its product range to meet the strictest hygiene and clean room requirements. A large number of enclosure systems are available that meet hygiene-based design rules. Aiming to give customers worldwide the confidence to use its products without having to carry out any additional test procedures, the company has allowed neutral bodies to conduct wide-ranging examinations: the sterile manufacturing technology department of VDMA (German Engineering Federation) awarded the products its QHD (Qualified Hygienic Design) seal of quality following a two-stage testing process. On the one hand, the QHD certificate verifies hygiene-friendly equipment and component design. And on the other hand, it corroborates the simplicity of the cleaning method. The Premium Panel command panel was investigated by Fraunhofer Institute for compatibility with clean room and high purity environments – and received the important IPA qualification mark for use in clean rooms of air purity class 1. Several demanding tests have to be passed before approval is granted: to test for the IP 69K degree of protection for instance, the command panels are mounted on a turntable and subjected to jets of hot water from a high-pressure nozzle at 80 °C and 100 bar.

Wired ready for connection

In order to meet hygiene requirements while weighing medications in granulated form, Schering needed a modern, dust-free working environment to accommodate IT components such as computers, keyboards and monitors at its Weimar plant – all inside a dirt-repellent stainless steel enclosure. Criteria such as safety, ergonomics and appearance all played a key role in the design of the new workplace. To meet these needs, Rittal developed an industrial workstation that combined a desk, PC tower and monitor housing.

The PC tower is conveniently mounted in a compact, stainless steel, AE-based lower enclosure section on a shelf integrated in the door. The 760 x 760 x 300 mm (W x H x D) enclosure is also fastened securely to the door by a harness, ensuring that the hardware components can be easily accessed. The lower enclosure is wired ready for connection. It has a socket strip integrated in the right-hand side panel for connecting the PC and the monitor. The 230 V power supply is introduced via an external socket. The foamed-in door seal ensures compliance with the IP 54 degree of protection, guaranteeing maximum safety for the installed hardware components. The stainless steel cross-members which ensure that the unit stands safely during stationary use can also be combined with double castors to provide mobility.

Easy to clean

The lower enclosure section is completed by an ergonomic, large-area worktop. Laminated with stainless steel and finished with overlapping, stainless steel edge bands, this surface meets stringent hygiene and clean room standards. Thanks to its smooth surface, the stainless steel rejects dirt and can be easily cleaned using aggressive agents. A stainless steel keyboard for data entry is integrated in the worktop. With its sealed, washable surface and IP 65 degree of protection, it is also highly suitable for use in damp environments. The keys of the piezo-electric stainless steel keyboard, specially designed for use in extreme applications, only need to be touched lightly to enter data. There are no raised keys with this IP 69K protected version – and no edges, hollows or gaps as there are with conventional keyboards.

IP 69K degree of protection

The industrial workstation is rounded off by a Premium-TFT 17”, which is securely fastened to the worktop by a support section. Together with its stainless steel housing, this 17“ TFT colour monitor has been granted IP 69K protection. The 17“ display is sealed by a special screen that allows a 1280 x 1024 pixel display. The high degree of protection of the Premium TFT and the empty enclosure variant Premium Panel – which are available in 530 x 360 x 120 mm (WHD), for example – is the result of a gap-free seal concept. The seal is located between two surfaces and optimally compressed by the all-round screw fastening, ensuring that a direct and EMC-safe contact is maintained between the enclosure and the cover.

cpp 435

Effective enclosure cooling

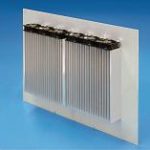

Where panel PCs and other heat loss sources are incorporated into the restricted space of compact operating housings, as it is the case in the Industrial Workstation at Schering, this almost necessarily results in unintended hot spots. To enable the optimum cooling of operating housings, Rittal now offers DCP Panel Cooling, a coolant-flushed system specifically for operating housing climate control. This cooling solution is able to dissipate heat losses of approx. 250 to 300 W. The original protection category of the housing is not affected. Unlike an air/water heat exchanger, the space-saving cooling unit can be mounted on the rear panel inside the housing, only the fluid connections are on the outside. As the heat losses are transported out of the housing by way of the coolant fluid, the housing inside temperature remains constant. Optimum air circulation over the internal cooling fins is ensured by six fan units, which together move over 300 m³ air per hour.

Industrial enclosures

Online seminar

Hannover Messe 2006

Share: