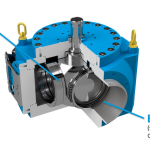

The special valves manufacturer Hartmann Valves developed an innovative concept with the multifunction ball valve with multiple safety barrier, which has already been submitted for a patent. The special feature of this flexible ball valve design is that it allows components to be inserted safely and easily in a wide variety of applications. Examples include a removable sieve basket filter, the insertion of pigs, a check valve in the ball that can be rotataed in its direction with a 180° turn, as well as measuring equipment or control wheels. All these components can be dismantled and interchanged. The result is a genuine multifunction ball valve that also offers full flow after removal of the respective built-in part.

Removable sieve basket filter

Together with the PCK Refinery Schwedt, Hartmann developed a ball valve filter unit with a removable sieve basket filter, which has a multiple safety barrier. The laterally integrated lock gate and the integration of the sieve basket filter in the ball enables the filter to be cleaned or replaced without any problems. In this way, time-consuming pipeline assembly at the pumping station of the crude oil pipeline between the Port of Rostock and the PCK Refinery Schwedt can be avoided in the future, thus increasing plant availability.

The sluice room is separately closed off by two additionally installed seat rings and the sluice pressure is monitored by pressure gauges. In the case of a leak in the first barrier of the pipeline to the dead storage, the second barrier seals against the interlock and thus the sluice gate can still be closed without danger. In this way, cleaning or replacement of the sieve basket filter can be done even when there is still residual pipeline pressure.

Integrated pigging ball valve

Even in the existing standard version, Hartmann scraper ball valves offer a clever concept as a space- and cost-saving substitution for expensive pig trap systems. In addition to its classic function as shut-off valve, the pig ball valve functions as a pig launcher and receiver. A laterally integrated lock gate, which is locked and secured by a bayonet system, allows scrapers to be inserted and removed easily, quickly and safely. An optional bypass in the closed position also enables cleaning if the media flow is not to be completely interrupted. In addition, the pig valve can be used to separate different products in a pipeline.

Multiple safety barrier

The Hartmann pigging ball valve with double or multiple safety barrier increases safety and plant availability and enables the safe and easy launching and receiving of scrapers – even with residual pressure in the main line. The design not only improves the pigging process, but also increases safety. As shown in the illustration, the sluice room is also separately closed off by at least two additionally installed seat rings and is monitored by pressure gauges. The additional safety barrier ensures that even if the first barrier of the pipeline to the dead storage is leaking, the second barrier seals against the interlock and the sluice gate can still be closed without danger. This innovative concept has already been awarded with the Primus Award 2021 in the valve category at the DIAM 2021 in Bochum.

Tailor-made for special requirements

With customised special ball valves, Hartmann Valves offers reliable shut-off solutions for demanding applications where standard valves reach their limits. They are designed for applications with pressures up to 1035 bar, temperatures from -200 to 550°C and high cycles up to 200,000 cycles per year or abrasive and/or corrosive media. In addition, special quick-closing valves, multi-way ball valves and valves in block design are developed and manufactured. One example is the Twin Ball Valve – a double ball valve that offers a compact and economical alternative to the use of several valves for increased safety requirements: Consisting of two ball valves in one housing, the construction length of a standard valve can be achieved with block flanges and safety can be increased by up to a factor of 4.

Metal-to-metal sealing

The meatal-to-metal sealing between the ball and the seat ring ensures a long service life and minimises the maintenance effort of the gas-tight ball valves. They are therefore more resistant and durable than soft-sealing systems. Even with the medium gas, high pressures and extreme high cycles, they fulfil a leak rate of A. Other key factors are the right selection and combination of materials, as well as surface treatments and special coatings, for example against corrosion. Regarding applications with demanding media, in addition to oxygen-suitable valves, the Hartmann solutions in the field of hydrogen are currently highly demanded. This includes hydrogen ball valves, the first delivered wellheads for large-volume underground storage as well as material suitability tests and tests for leak-tightness. The multifunctional ball valve is also available in a special design for hydrogen applications.

Hartmann Valves GmbH, Burgdorf-Ehlershausen