Production processes that run 24/7 need reliable and energy efficient drive systems to maintain a cost effective process. For one pharmaceutical manufacturer the drive for efficiency led it to replace some existing equipment with the latest IE4 electric motor technology from Bauer Gear Motor, cutting the kW power size by 60 % whilst also reducing the weight and increasing the overall drive efficiency. Bauer was able to improve the latter by approximately 35 % while maintaining the required quality of mixing.

Author Markus Kutny Product Manager – Energy Efficiency Solution, Bauer Gear Motor

Fresenius Kabi Austria is a subsidiary of Fresenius Kabi, the international healthcare group: its plant in Linz manufactures active pharmaceutical ingredients (API) such as lactulose, hydroxyethyl starch (HES) and sinistrin and houses a pharmaceutical production unit for related finished products. The lactulose line operates 24 hours a day and seven days a week with an order based, just-in-time production system that makes sure only APIs with a maximum shelf life are delivered to customers. A significant part of the production process involves the product being held in large vats that are continuously stirred by agitators, driven by electric motors.

It was this process, amongst others, that was under scrutiny in terms of energy and process efficiency. Fresenius Kabi approached Bauer with a request for support in investigating a more efficient drive system. At the same time they wanted to engineer in flexibility that would guarantee the solution’s ability to perform even if certain process specifications were changed.

Assessment of the agitator drive

The first step was to carry out an assessment of the existing equipment, which comprised an IE2 (2-pole) direct-on-line (DOL) asynchronous geared motor (ASM) rated at 18.5 kW with a nominal efficiency of 91.2 %. This was connected to the agitator paddles that turned at about 105 rpm with an approximate load of 1632 Nm. Initial measurements showed that this drive arrangement was working at 10.5 kW and therefore at reduced energy efficiency due to the part-load conditions. At this point the production engineers explained that they wanted to modify the geometry of the agitator and reduce the speed from 105 rpm to just 53 rpm.

The new agitator design was trialled at the reduced speed to ensure that the product in the vat was properly mixed; confirmation of this allowed Bauer to continue with the selection process for the geared motors using the new parameters. To begin with, Fresenius Kabi was interested in installing an IE4 asynchronous motor (size 132) with a nominal efficiency of 92.6 %; however, after consulting with Bauer, they decided to use an IE4 permanent magnetic synchronous motor (PMSM) (size 112) to achieve even greater efficiency gains. Bauer’s consultation started with a comparison of the running costs of the original equipment with those of the latest motor technology. This was accompanied by calculations of the total cost of ownership (TCO), which provided a clear picture of the differences in energy consumption between the ASM and PMSM designs as well as detailed technical calculations of the bearing lifetime.

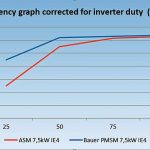

As part of the project, Bauer proposed the BF60 and BK60 geared motor models, which would provide a 7.5 kW IE4 PMSM with a helical or bevel gearbox. The most significant advantage compared to an IE4 ASM is seen when operating at lower speeds or under part load. Although both the ASM and PMSM motors were classed as IE4, the nominal efficiencies were 92.6 % and 92.1 % respectively. However, the ASM efficiency was stated for direct-on-line (DOL) duty and after this was corrected for inverter duty, the figure was 90.2 %. There was also a considerable difference in the physical mass of the motors, with the ASM weighing in at 84 kg and the PMSM at only 31 kg, which can be crucial in certain applications.

The chart shows the calculated differences at 50 Hz for various loads on the motor. The ASM at part load shows a much greater reduction in efficiency than the PMSM under the same load conditions. At less than 50 % load the differences are extreme. A further factor to be considered is that the efficiency is also lower if the speed is variable.

Comparison of IE3 technologies

During the consultation phase Bauer was able to reference data from a physical benchmark test that was carried out on an IE3 ASM and IE3 PMSM. In this example the nominal efficiency of the ASM was 89.6 % while the PMSM motor was rated at 90.8 %. As with the IE4 examples above, there was a considerable difference in the physical mass of the motors, with the ASM weighing in at 56 kg (size 132) and the PMSM at only 31 kg (size 112). Efficiency charts demonstrated the advantages of the PMSM if the application requires a lower speed or less than full load from the motor. They showed that the efficiency of the ASM is substantially lower than that of the PMSM at lower speeds (6 Hz) when operating at part load. This data can also be applied to the IE4 models. These are deciding factors which visualise the true efficiency of the motors to the client in a real application.

Built-in reliability

The BF and BK series are available with power ratings up to 45 kW, producing an output torque from 80 to 18,500 Nm at speeds from 0.2 to 280 rpm. The design is completely enclosed and sealed against dust and water spray to IP 65 as standard, with IP 66 and IP 68 optional. This ensures that all geared motors can be used outdoors or in wet or dusty environments without an additional enclosure. There is also a PMSM solution in both the IE3 and IE4 efficiency classes for applications in hazardous areas.

Reliability is built in with generously sized ball or roller bearings, case hardened, forged and ground gears and internally and externally reinforced gearboxes, all of which ensure a long, low-maintenance service life. A hardened wear sleeve and spray ring at the rotor seal guarantee a reduced sump capacity and reliable lubrication for many years of leak-free performance. All product lines are supported by a high level of part interchangeability for all geared motor components. Although the nameplate indicates the rated efficiency of the motor, it is also important to take a close look at the efficiency of the geared section, which can be affected by friction in the oil, bearings and seals. Bauer was able to improve the overall drive efficiency by approximately 35 % while maintaining the required quality of mixing. However, these gains in efficiency must not be achieved at the expense of reliability, which is heavily influenced by the operating temperature of the powertrain. With this in mind, thermal imaging equipment was used to obtain accurate information on the normal operating temperature of both the motor and the gearbox.

The attention to detail of the Bauer engineers in providing a comprehensive demonstration of the potential energy saving with IE4 PMSMs and their deep application know-how were what tipped the scales for Fresenius Kabi. Furthermore, after the first components performed to the expected levels, additional units were ordered to complete the comprehensive overhaul of the original process equipment.

Hall 25, Booth C3

cpp-net.com/0115418

Share: