All too often on the journey to Industry 4.0, the second step is taken before the first. For some time now, promising scenarios have shown the type of potential that can be achieved if industrial companies were to use cyber-physical systems. The basis for this is selected automation data, especially from the field level. A considerable amount of this data is already being generated, but only a small proportion is actually evaluated and processed into information. Before this data can be fully utilised to create added value for digitalisation, it needs to be properly exported from the field or process control level (via a side channel) to higher levels, such as a cloud. Concepts like NOA (Namur Open Architecture) illustrate how this can be done in large plants without compromising system availability and the safety of core processes.

Another prerequisite on the journey to smart production is that it should be as straightforward as possible to read this data. Only then will it be possible for this data to be widely used, for example, for monitoring and optimisation systems in process automation. These and other challenges associated with the contextualisation of data have not yet been adequately addressed.

Reduction of complexity

Using the NOA interface, based on OPC UA, data such as diagnostic data from existing field devices and data from any other low-cost sensors and controllers should be made accessible, so that it can then be utilised by various applications through read-only access to not impact the actual core process. Although they may appear relatively straightforward at first glance, the NOA core requirements formulated by Namur only hint at the complexity involved. The most important requirement concerns consistently high system availability and system safety. In addition, open system interfaces are required, as is the use of existing standards. However, those familiar with the gradually evolved and therefore heterogeneous landscape of process plants in Germany alone will know that finding solutions that work in equal measure for both existing and new plants is no small matter. But above all, as Namur states in its Guiding Principles for NOA: “Usability, reduction of complexity, and economic efficiency are the main success factors”.

No unstructured collection of data

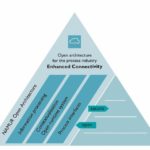

The aim must be to ensure connectivity as easily and inexpensively as possible, and to implement all general conditions such as IT/OT security within this context. Despite the wide range of transmission protocols involved, the integration effort should be near non-existent. In view of these requirements, one thing must be avoided: the unstructured collection of data. Phoenix Contact therefore recommends an architecture in which data read via a process interface is contextualised first. This means that it is made available in an aggregated and structured format before it is used in the actual information processing level. All this is ensured by the “enhanced connectivity system” (Ecosystem). Without a system of this type, the integration effort largely depends on process interfaces and protocols.

At the process interface level, this integration is largely handled by the Ecosystem, for example, through the impact-free automated reading of Hart data. At present, this is only possible with significant engineering effort, as the Hart information is available as raw data and makes little sense without context. Initial solutions are available in the form of Hart IP gateways or Hart IO cards, which can be used to read the raw data collected from field devices.

Download of functionality

To reduce the engineering effort for users, the Ecosystem provides support at the contextualisation level, as it carries out the preprocessing via a gateway on the edge, for example. Data mapping with the aid of device-specific description (EDD, FDI) transforms raw data, process data or diagnostic data into valuable, usable information.

PA-DIM (Process Automation – Device Information Model) will be the standard used for this. Users will no longer have to deal with the complex process of data mapping; in future, they will be able to download the functionality in the form of an app from the Phoenix Contact app store. The app makes the data available in context for further evaluation or aggregation of information. At this level, it is also possible for an open runtime system, such as the PLCnext Ecosystem, to analyse the information “on the edge” and, using complex algorithms (high-level languages via Matlab or C++), utilise this information for predictive maintenance or to optimise processes.

Connectivity with other systems is supported at the information processing level with cloud connectors, various cloud applications, and software as a service (SaaS), which can be accessed via an online platform.

Hart data to be stored in a cloud

As mentioned, the data diode model requires the Hart protocol to be used solely as a one-way street, i.e., write access is prevented. In addition, secure routes, e.g., using a security router, are recommended for reading Hart signals. The Hart signals that are obtained can be collected in a local database or a cloud.

In principle, it is easier to use a cloud: data cannot be lost, accessibility is optimised by the provider, and cloud services are convient. In practice, a Hart gateway with OPC UA interface acts as the link between the field and the higher-level system. OPC UA supports various security measures. The data stored on the OPC UA server can be used for suitable and authorised higher-level systems, where each system can select the data it requires.

Up to 40 sensors can be connected to the Phoenix Contact Hart gateway extended with the OPC UA server. The information (such as identifiers or diagnostic values) is read cyclically – without any configuration effort. This opens up various possible applications for the operator, such as plausibility checks, predictive maintenance or use by external specialists.

Optimised connectivity

As explained, data can be made usable with manageable effort. IoT gateways direct diagnostic information and other information to a cloud or server where it can be evaluated, for example, by web services – better than in standard maintenance tools. In future, device manufacturers will support this with big data analysis based on a huge amount of data from their worldwide database. The NOA concept in conjunction with various web services opens up significant potential for increasing the efficiency of plants. The effort involved on the part of the operator will decrease further. Those who want to ensure (enhanced) connectivity will be able to benefit from Industry 4.0 and artificial intelligence in future without having to invest excessive resources.

New technologies like 5G and Ethernet to the Field, in process automation specifically APL (Advanced Physical Layer), will play an important role. With its higher bandwidth and availability, 5G communication enables new wireless applications. APL, as a prerequisite for using Ethernet (Profinet) in the Ex area, makes it easier to implement big data applications, as large volumes of diagnostic data can be transmitted from the field at high speed. The restrictions imposed by previous fieldbuses no longer apply and the handling of promises is also easier. All in all, both 5G communication and APL will provide optimised connectivity that supports the specific requirements of Industry 4.0 and smart production more effectively than current solutions.

Phoenix Contact GmbH & Co. KG, Blomberg, Germany