Sometimes it’s worthwhile looking at older technologies from a new viewpoint. For a long time the microwave barrier was considered to be something only for niche markets. This technology is now experiencing a rediscovery. Its great advantage: It combines simple technology with boundless freedom.

Clemens Hengstler

Centimetre-thick dust deposits, frosty ice crystals, thick cobwebs – it’s not unusual for today’s measuring instruments to have to put up with such adverse environmental conditions. For example, cobwebs can impair traffic control systems and regulate the traffic down to 40 km/h, ice layers can prevent an emergency brake from being triggered at a gondola entry and huge coal deposits can bring conveyor transfer stations to a standstill. However, users want measuring instruments that work reliably even under such rough conditions. Vega Grieshaber has introduced a compact instrument, based on the newly rediscovered microwave barrier technology, that can reliably and contactlessly detect the limit level of bulk solids and liquids.

Microwave barriers are nothing new – they have been used for level detection in extremely harsh operating conditions for quite some time. For broader use, however, the instruments had to be revised. Vega decided to integrate this measuring principle into its plics plus instrument generation. The result is the VegaMIP 61 microwave barrier, which is especially tuned to the requirements and needs of applications in rough environments.

VegaMIP 61 can be used as either a maximum or a minimum sensor. The microwave barrier also offers numerous possibilities for liquid level or object detection. Its contactless measuring principle has proved to be particularly advantageous for abrasive media like minerals or ores as well as in applications involving very high temperatures. The instrument is impervious to soiling, build-up and baked-on deposits. Changing medium properties, such as density or material dampness, affect the instrument no more than do the temperature of the medium or intense dust generation. To detect the limit level, VegaMIP 61 simply measures from the outside of a vessel through a microwave-permeable window made of ceramic or plastic. In the case of metallic containers, the sensor can be fitted to a suitable mounting socket or in front of a plastic, glass or ceramic window.

The fact that few mistakes can be made when implementing the sensor is especially appreciated by users. While radar technologies or guided microwave open up many fascinating options – but at the same time require a lot of detailed application knowledge – the functional principle of the microwave barrier is more straightforward and only mi-

nimally influenced by the way in which it is implemented.

The microwave barrier principle is basically comparable to that of a light barrier. Instead of a light beam, however, a microwave signal with a frequency of 24 GHz is used. The microwave barrier consists of a VegaMIP T61 transmitter and one or more VegaMIP R61 receivers. The transmitter sends a microwave signal, which is focused by a horn antenna, to the receiving unit mounted opposite. If medium gets in between the transmitter and the receiver, the microwave signal is damped. The receiver measures the attenuation of the received microwave signal and generates a switching signal from it. Thanks to the large dynamic range of 80 dB, an operating distance of more than one hundred metres is pos-sible. If the signal is attenuated by dust, dirt or other installed equipment, the sensitivity can be easily adapted with two pushbuttons. This guarantees switching reliability even if build-up and dirt collect on the windows. The response speed of the receiver can also be freely adjusted between 100 ms and 20 s.

Flexible adjustment

Installation is equally simple. Neither an adjustment module nor a PC connection is required. What’s more, this compact device doesn’t need a signal conditioning instrument, which means its wiring requirements are comparatively low. Even if local conditions are not exactly as expected, the new sensor can still be quickly set up and commissioned. In addition, the sensor can be easily attuned to the conditions in the field using a mechanical adapter, e. g. a metal plate, which diverts the signals like a mirror. A simple metal tube is also suitable as a signal guide. For operation at very high temperatures, a mounting adapter with ceramic process separation is available. It is merely mounted between the vessel and the sensor.

Another advantage is that the signal quickly provides the user with all essential information. The VegaMIP T61 transmitter requires no adjustment and the operating mode is signalled by an LED. The signal strength is indicated by an LED strip on the VegaMIP R61 receiver.

VegaMIP 61 fits perfectly into Vega’s plics plus concept and offers all the advantages of a modular assembly system. Users can choose between housings made from plastic, aluminium or stainless steel as well as different antenna systems and process connections. Normally, it doesn’t pay to develop special antennas for niche applications. However, the situation is different with VegaMIP: The instrument operates at the same frequency as radar sensors in general, with the result that a wide selection of antennas already exists, such as the completely encapsulated version with 3 A approval for the food industry or an angled antenna for the steel industry.

From crusher to lock

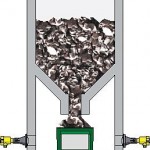

VegaMIP’s robust and reliable design contributed greatly to its success in the market, which became apparent about six months after its launch. What amazes most here is its enormous range of applications. The instrument is used, for instance, for limit level detection in plastic containers, to which it doesn’t even have to be fastened. The container is simply placed between the transmitter and the receiver. The microwave barrier indicates when the defined level is reached. VegaMIP also has several advantages when it comes to level detection at conveyor transfer stations, e. g. in coal processing systems in power plants or in transport systems for fertilisers or soda lye in pellet form. The sensors operate independently of the medium properties and switch reliably if product piles up at the transfer station.

Like a light barrier, the microwave barrier can also be used for site supervision. Microwaves are not affected by dust, rain or fog and react only minimally to instrument soiling. Typical applications are truck loading in quarries or collision avoidance. The microwave barrier even recognises ships coming and going through a lock. Once again, the measurement is completely independent of weather conditions like fog, rain or snowfall. Thanks to its metal housing with IP 68 protection, the sensor can even be flooded with water.

In short, these examples not only reveal the wide application range of VegaMIP and the microwave barrier in general, but also show how an underestimated technology can capture the market outside its established field. Extreme ease of use and unshakeable reliability, proven, versatile accessories such as antenna systems, housings and process connections, as well as the assurance that – in spite of its great simplicity – the instrument is based on state-of-the-art measurement technology and a convincing product concept like plics plus are the key factors here.

Online-Info www.cpp-net.com/2210428

Share: