Marking in the process industry is not a simple subject due to the strict requirements which apply there. They include high resistance to environmental effects – and labels that are permanently legible. If marking is performed in areas where there is a risk of explosion, static must also be prevented. To meet these requirements, Phoenix Contact offers various systems for a wide range of materials.

Author Sven Heier Product Manager Marking and Installation Business Unit, Phoenix Contact

Markings are used in many different ways in the process industry, which is why the requirements differ from case to case. In the food industry, the materials employed for markings should be as insusceptible to contamination as possible while offering high resistance to aggressive cleaning agents. The same also applies to the chemical industry. IEC/EN 60079-0 defines the requirements for hazardous areas in the process industry. The oil and gas industry, on the other hand, places rigorous requirements on the weather resistance of marking components, for example high UV resistance as per ISO 4892. The afore-mentioned industries often have additional – sometimes in-house – regulations with requirements that are even stricter than the generally applicable standards. One important factor across all industries is the resistance of the markings to wiping as per DIN EN 61010-1 in connection with aggressive media such as acetone, ethanol or MEK (methyl ethyl ketone).

Since there is no single solution that satisfies all of these demands, Phoenix Contact offers a number of different marking systems. They include standard thermal transfer technology, innovative UV LED technology and laser technology based on the new Topmark Laser system. Each marking technology has its advantages.

Thermal transfer printing

The thermal transfer technology employed in the Thermomark Line product line labels the target medium using a print head and ink ribbon. This product line caters for two formats: rolls, which are generally used as labels, and markings on card stock material. For hazardous areas in the process industry, Phoenix Contact has developed a product line that meets the requirements for adhesion and resistance to wiping as per IEC/EN 60079-0 and DIN EN 6101011. The necessary resistance to wiping is achieved by means of a special ink ribbon.

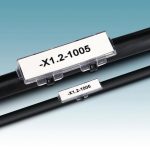

US (universal sheet) cards are used as markings for terminals, cables, devices and systems. UCT (universal card thermal transfer) materials are suited for the same applications as US cards but in a different format. The cards have a different height and can be snapped into the grooves of terminal blocks.

UV LED technology

With UV LED technology, on which the Blue-mark CLED printer is based, the fluid is hardened by UV light. This product line draws on the US cards and UCT mats as carrier materials. Since printing with UV technology is similar to a conventional ink jet printer and there is no contact printing as there is in a thermal transfer printer, the choice of materials plays a less important role. Phoenix Contact also offers Bluemark CLED products for hazardous areas.

Permanent marking by laser

Laser marking provides especially high durability because, in contrast to other printing technologies, no marking medium is applied to the target material; instead, the laser beam alters the material itself. The Topmark Laser is designed for different types of marking. Either the material is removed from the solid substrate or – for anodised aluminium – the topmost layer is lasered off, resulting in a colour change. With annealing marking, too, a colour change is brought about by applying a large amount of energy to the material with the laser. However, with this method the surface of the material remains completely flat. This type of labelling is ideal for the food and chemical industries, because the marking does not produce any surfaces which are susceptible to contamination. Labelling created with the Topmark Laser is highly durable and resistant to wiping – and since the marking is applied to the material itself, it can only be removed by destroying the material.

The Topmark Laser product line supports a number of materials – from metals such as stainless steel or aluminium to polyacrylate film, which can be marked and cut in a single processing step. In addition, this film offers a high degree of temperature resistance from -40 °C to +300 °C. If desired, it can also be used to create and cut out machine labels. Marking labels can be produced for other applications too, as they can be cut to custom sizes and shapes. The maximum labelling area is 180 x 180 mm. Topmark Laser provides automated handling with a stacking and unstacking function for materials in the UCT product family. The magazine holds up to 80 mats depending on the contour. All in all, the Topmark Laser line includes over 400 marking materials.

Intelligent marking with RFID

Irrespective of the type of printing process, new kinds of markings like RFID technology are also finding their way into the process industry. RFID still supplies information even if the labelling has been partially destroyed or completely removed from the material due to cleaning agents, solvents or other aggressive media.

Phoenix Contact offers marking labels that completely surround the RFID chip. Markings applied in this way enable the chip to be identified fast. Even if they are removed altogether, information can still be read out from the RFID chip. RFID technology is especially helpful in areas with severe soiling or contamination or no light. This technology is already gaining ground in the upstream oil production sector.

Summary

Due to the growing demands on markings, it is almost impossible to find a simple yet comprehensive solution for all applications in the process industry. Each marking project should therefore be considered in its specific use context. Phoenix Contact offers integrated solutions from planning to application:

- Clip Project planning and marking software

- Printing systems with thermal transfer or UV printers and laser markers

- Wide range of materials for every printing system

Hall 9, Booth F40

cpp-net.com/0115420

Share: