Everyone is talking about Industrie 4.0 (IIoT). And we have long since moved on from questions of whether or not to deploy IIoT and instead are now focusing clearly on practicalities. However, while most companies have realized that they will need to plan for projects that target process optimization, questions about specific use cases and corresponding technologies are much harder to answer.

Long-term solutions are needed

There are many approaches to successfully implementing digital transformation – and a correspondingly large number of providers and products. Often, however, capacity bottlenecks, personal preference, or even a lack of expertise on the part of users result in only a few solutions being evaluated. Another factor here involves the long lifecycles usually relevant for process plants, which require any new project to prioritize the long-term usage of any new systems planned. So the key question to answer is whether the solution being considered today will still meet requirements five or even ten years down the line. Picking an ideal solution is made harder by the sheer wealth of choice, however, as well as the problem of accurately predicting future difficulties. Often, a particular solution is chosen out of a simple need to ensure that a specific type of process-related data connectivity can be provided. In some scenarios, this is achieved by software interfaces that retrieve the data from the control layer, but this approach is not feasible for all use cases. Making changes to the control layer is unwise for critical processes and the data available on this layer are only half the story anyway: this layer is simply too indirect to provide all of the relevant values. For many applications, things only get interesting once we look at data traffic directly on the bus systems – where the data are created and handled. However, for older, conventional technologies like Profibus and Hart, hardware gateways will be needed to provide physical access to the networks in the first place. Yet rolling out this additional hardware involves extra effort and a certain amount of risk. This means we are back to square one: deciding on a solution that requires hardware access involves taking the risk that this access will then only be usable within the scope of the solution in question. Additional solutions consequently require extra effort and access points that introduce new risks. While uninstalling one piece of software and rolling out another is a relatively manageable task, a decision to replace hardware in facilities that may have thousands of networks is a different matter entirely.

Two gateway solutions that provide data over standard interfaces

Introducing new application software does not always require replacing the corresponding hardware access points, however, as long as providers have prioritized standards compliance. After all, specifications are not going to change for legacy technologies, protocols and networks – nor are any of their available data types (e.g. for process, diagnostic and inventory data). This is where Softing’s Smartlink product family comes in.

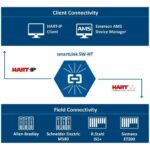

The Smartlink gateways are available as a hardware or software product and provide a full set of data from field devices and networks using standardized interfaces. This is independent of whether the upstream application analyzes process data using AI, provides configuration interfaces for field devices, or is a piece of cybersecurity software used to detect unwanted visitors. Thanks to Smartlink’s support for open communications standards like OPC UA, MQTT or Hart IP, the data connectivity it provides can handle the implementation of any kind of use case. At the field end, integrating Smartlink is a straightforward, low-risk task that can be handled with zero downtime and without any need for a plant shutdown. Firmware updates ensure that all interfaces on the application end are kept up-to-date at all times. This means that the Smartlinks are the first and only change needed for a plant looking to get up to speed with the IIoT. As of now, the Smartlink product family from Softing comprises the two products Smartlink HW-DP and Smartlink SW-HT.

The first, Smartlink HW-DP, is a hardware gateway for Profibus DP that can be integrated into a Profibus DP segment and then facilitates Ethernet-based access to Profibus devices. The gateway also provides access to Hart devices that are connected to Profibus remote I/Os. From the Ethernet end, access is available to the Hart devices via Hart-IP and FDT DTM. Profibus devices are also available via FDT DTM, while their process data are provided using OPC UA and MQTT.

The second product, Smartlink SW-HT, is a Docker container-based software application. This uses Hart-IP to facilitate access to Hart devices that are connected to remote I/Os and so, in turn, reachable over Ethernet. As of now, remote I/Os from Allen-Bradley, Schneider Electric, and R. Stahl can be used. Version 1.30, which is planned for early 2023, will also support ET200 Remote I/Os from Siemens and the FDT DTM interface.

The Hart-IP and FDT DTM interfaces allow the use of asset management applications like Emerson AMS Device Manager or Endress+Hauser Fieldcare for device parameterization and monitoring. In addition, IIoT use cases like a process optimization project can also be implemented using the OPC UA and MQTT interfaces.

During 2023, Softing will also be expanding the Smartlink family with products for Profinet: Smartlink HW-PN and Smartlink SW-PN.

Softing Industrial Automation GmbH, Haar

Author: Thomas Rummel

Managing Director,

Softing Industrial Automation

Author: Thomas Schwarzenböck

Product Manager,

Softing Industrial Automation