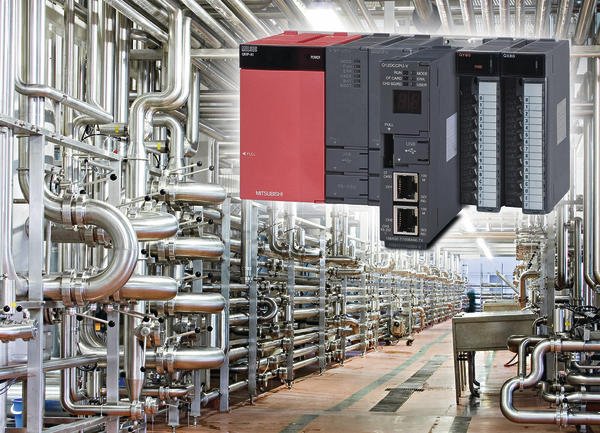

Mitsubishi Electric has moved the execution of recipes traditionally carried out using PCs as well as interfacing to the process and fundamental process control to the C Controller which is integrated in a secure PAC environment (PAC – Process Automation Controller). The C Controller runs the jointly developed Inea software which also functions as a batch execution engine within the secure control environment.

As a result, PCs are no longer required on the shop floor in order to manage and support this type of process, thus removing a security risk from production since non-industrialised PCs are far more susceptible to faults and they only have lim-ited protection against computer viruses or hackers. The C Batch system only uses PCs for the non-critical creation and editing of recipes. Connection is realised via a single interface which can be efficiently controlled in order to keep the control system and production facility safe from cyber threats.

Hall A5, booth 519

cpp-net.com/0112454

Share: