One problem that has increasingly become the subject of international focus in recent years is the danger caused by the Legionella bacterium. In humans, Legionella can cause not only the relatively harmless Pontiac fever but also the more dangerous Legionnaire’s disease. Legionnaire’s disease is a reportable condition in Germany. The Robert Koch Institute, in its Epidemiology Bulletin 13/2015, announced that the number of cases reported between 2001 and 2013 had risen from just under 200 to over 900. This trend means that more work needs to be done to stamp out the causes.

The basic steps

The first key step for reducing the risk of Legionella in cooling towers is to use modern droplet separators. These ensure that 99.99 % of all un-evaporated water remains in the circuit, preventing it from representing a potential danger. To do this, the droplet separators must be installed correctly and undergo regular testing and maintenance. Holes or large gaps can lead to a deterioration in performance. Yet even a perfectly functioning droplet separator will always have residual discharge.

This is why consistent and appropriate water purification is the second step towards reducing risks. Even with the best water purification system, there are parts of a cooling tower in which purification alone is unable to achieve complete disinfection. Pockets of bacteria can develop and spread via the open system, causing harm to the surrounding population. This is especially critical if the cooling towers are located next to hospitals or on the roofs of hotels, for example.

Reducing dead zones

The third aspect is good water distribution within the cooling tower. This not only ensures effective heat transfer; it also means that the treated cooling water covers the heat transfer surface, reducing dead zones there. These zones are renowned as areas that encourage the growth of bacteria. There are limits here too, and even optimal water distribution cannot fully inhibit the growth of bacteria on the relatively large surfaces of the packing materials.

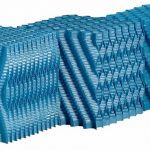

In the new 42nd BImSchV (Federal Emissions Protection Act), the legislator has therefore prescribed that a suitable choice of materials be made for the packing materials – the fourth key step. The basic principle behind this minimum requirement is that the materials should not act as nutritional substrates for micro-organisms. Installations made from untreated paper, for example, are therefore unsuitable for such coolers. On the other hand, the synthetics normally used, such as polypropylene (PP) or polyvinyl chloride (PVC), provide the required properties, though they do not prevent biological deposits from forming. Sanipacking packing materials were therefore also developed with the aim of preventing bacterial growth.

Efficient packing materials

Sanipacking packing materials reliably inhibit the growth of bacteria. This means that they contribute to minimising the risk of Legionella infections and also prolong the materials’ high-performance phase. This is made possible by a synthetic especially designed for wet cooling towers, which is treated with additives to inhibit cell growth and hence the proliferation of bacteria.

The bacteria-inhibiting effect on Legionella has been proven in accordance with the international standard ISO 22196 (JIS Z 2801). For this test, Legionella bacteria are applied to the film and cultured at 36 °C for 24 hours. After this time, the number of bacteria still alive are counted. While the number of bacteria on a non-additive cooling tower film remains almost unchanged, there is a reduction of more than 99.99 % in Legionella bacteria on Sanipacking products.

This lightweight material is also free from arsenic and heavy metals and resistant to decay and mould infestation (in accordance with ISO 846). It is additionally resistant to corrosion and UV radiation as well as to most chemicals. It is 100 % eco-friendly, offering the same advantages and efficiency as non-anti-Legionella materials.

In order to maintain the full bacteria-inhibiting effect for three to five years, the surfaces of the packing material must be kept permanently free of inorganic accretions through effective water purification and regular maintenance, since failure to do so will impact on their anti-bacterial effect.

On top of this special Sanipacking action, it is easy to heat the basic PP material briefly to 70 °C in order to make use of other options for disinfection.

Easy installation, small pressure loss

As mentioned earlier, droplet separators that are not in direct contact with the water distribution system also represent a potential risk. Enexio provides versions with the Sanipacking design. If these are used as standard for newly built or converted cooling towers, the risk of Legionella can be reduced even further.

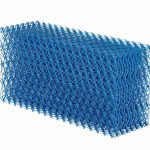

Droplet separators such as packing materials with these features are made up of special, individual, polypropylene films that are sealed together systematically to form stable modules with a criss-cross structure. Apart from these, Enexio offers NET 150, a highly efficient mesh packing material in Sanipack-ing quality. Its wafer-shaped modules can withstand hot water temperatures of up to 80 °C, or 90 °C for short periods.

Sanipacking packing materials and droplet separators are available in a variety of designs for use in virtually any situation. Installation is economical and heat exchange takes places with only minimal pressure loss. The manufacturer has equipped a wide range of products with the Sanipacking effect, enabling the risk of infection to additionally be minimised for various types of cooling tower design and packing material.

The use of this technology alone, however, is not enough. As in many sectors, safety is the sum of many different measures. And so it is in the battle against Legionella. It is only the sum of all measures that produces a coherent overall picture. For more information on how cooling tower manufacturers and operators can protect themselves from the risk of Legionella by optimising the plant design, please refer to the following articles:

- VDMA Standard Sheet (VDMA 24649) – contains important practical tips for the operating manual

- 42nd BImSchV – describes the new legal regulations governing cooling towers in Germany

- Eurovent REC 9/7 – contains recommendations for the safe operation of cooling towers

- ASHRAE Standard 188-2015 – regulates hygienic ratings in the USA and offers information from this perspective

Online search: cpp0318enexio