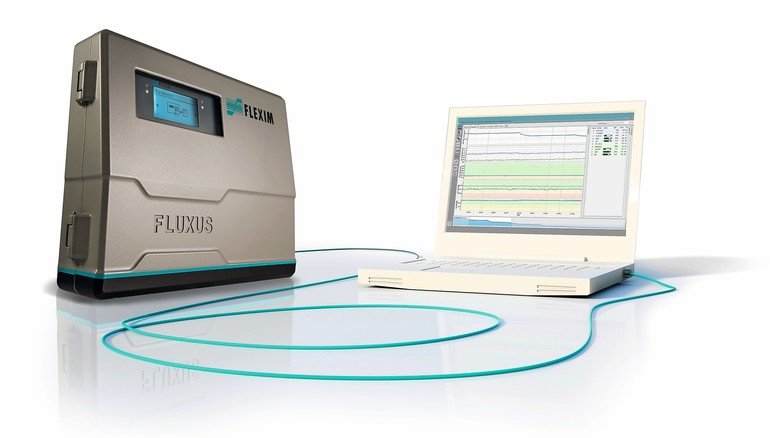

Due to its practical advantages external, non-invasive flow measurement with clamp-on ultrasonic transducers has become a standard measuring technique over the past twenty years. With the Fluxus F/G 721, Flexim now presents a clamp-on ultrasonic system that sets new standards with advanced signal filtering, improved signal algorithms and a high-frequency processor.

Clamp-on ultrasonic flowmeter for liquids and gases

Highly dynamic processesrecorded in real time

Due to its practical advantages external, non-invasive flow measurement with clamp-on ultrasonic transducers has become a standard measuring technique over the past twenty years. With the Fluxus F/G 721, Flexim now presents a clamp-on ultrasonic system that sets new standards with advanced signal filtering, improved signal algorithms and a high-frequency processor.

Today, non-invasive, ultrasonic flow measurement is only an outsider measuring technique in the technical sense: clamp-on ultrasonic transducers are simply attached to the outside of the pipe – without any interruption of operation or any risk of leakage. Regardless of what is flowing inside the pipe – from high-purity water in the pharmaceutical or semiconductor industry to highly explosive natural gas under high pressure during gas production and transport – clamp-on transducers always measure from the safe side, are not subject to wear and tear from the medium flowing inside and pose no risk of impurities being introduced. These former underdogs have long become extremely popular because they meet the main requirements for industrial production, namely the highest level of safety for people and the environment on the one hand and maximum plant availability on the other.

Over the last 25 years, Berlin-based Flexim has become an expert in the field of ultrasonic measuring technology. Flexim recently received official confirmation, so to speak, of the reliability of its clamp-on ultrasonic systems when the Fluxus F/G70X and F/G80X series flowmeters received SIL certification. At last year‘s Achema trade fair, the company was able to unveil yet another highlight with the Fluxus F/G721. These flowmeters are not simply more advanced versions of successful predecessors. The 721 series seen in Frankfurt represents an entirely new generation of devices. It is based on a significantly more powerful hardware design. Not only does this provide the foundation for even better performance in terms of reliability, measurement accuracy and dynamics; it also opens up many more options for bidirectional communication.

Powerful ultrasonic twins

In fact, this ultrasonic system isn’t just one device, it’s actually two: the Fluxus F721 is used for non-invasive flow measurement of liquids whereas the G721, which is externally identical in design, measures the flow rate of gases. Both systems are also available in two different housings, namely an aluminium one for standard applications and a stainless steel one for use in highly corrosive environments or potentially explosive atmosphere (Atex, IEC EX Zone 2, EAC TR TS, Inmetro).

Sophisticated signal filters, significantly improved signal algorithms and a high-frequency processor make the Fluxus F/G721 the ideal flowmeter for even the most challenging applications. The ultrasonic system adapts itself to the respective conditions and automatically compensates for disturbances such as structure-borne sound and beam drift. The extremely fast measurement output enables highly dynamic processes to be recorded in real time. Measuring transmitters and transducers are calibrated independently of each other in a patented process without the influence of application-related disturbances. This ensures the highest possible measuring accuracy in the field regardless of the combination in which the measuring system is used.

Wide range of applications

The Fluxus F721 is suitable for non-invasive flow measurement of virtually all liquids, from very narrow to very large pipes, irrespective of the prevailing pressure inside and over a very wide temperature range. In conjunction with the patented Waveinjector transducer attachment, the flow rate of liquids can be measured non-invasively at temperatures from –190°C (e.g. LNG) to over +600°C. The highly developed technology of the Fluxus F721 also allows reliable, non-invasive flow measurement of liquids with a high solids or gas content. In addition, the acoustic measurement method is characterised by extraordinary sensitivity and dynamics: even extremely low flow rates of a few litres per hour can be detected accurately.

The powerful signal processing functionality of the Fluxus F/G721 really plays out its advantages during non-invasive flow measurements of gases. The devices can now also measure on steel pipes without any problems above a pressure of 3 bar. The Fluxus G721 is equally ideal for consumption measurements in compressed air networks. With plastic pipes, it is much easier to feed acoustic signals into the gas flowing inside. The non-invasive measuring technique does not require any minimum pressure in this instance. It can even measure at negative pressure.

At Flexim, the non-invasive development of energy saving potential is seen as an especially exciting application for this exceptionally versatile ultrasonic system. Regardless of whether the non-invasive technique is used to measure thermal output in a district heating network or to determine the efficiency of an industrial heat exchanger, complete security of supply is guaranteed at all times. Thanks to its high sensitivity at low currents and highly accurate, paired temperature transducers, the Fluxus F721 is also suitable for accurate consumption measurements in air conditioning systems.

Fit for Industry 4.0

The Fluxus F/G721 supports all the usual communication protocols. Hart, Modbus, Foundation Fieldbus, Profibus PA and Bacnet allow bidirectional field communication, parametrisation and online diagnostics. Customised configurations ensure optimum adaptation to the respective application.

The Fluxus F/G721 is also a step ahead when it comes to user friendliness and diagnostic functionality: it can be parametrised in next to no time via its USB interface. The Ethernet connection opens up additional possibilities for bidirectional communication. The advanced self-monitoring capability of the instruments and the option of event-driven data logging add particular value in industrial practice. The measuring transmitters monitor the measurement quality continuously and automatically. These values as well as all other measurements and even pressure or temperature values fed in externally, for example, can be selected as triggers for functions of the user’s choosing. If, say, the measurement quality falls below a defined value, a measurement storage rate with high temporal resolution can be activated. This freely configurable trigger function is suitable not only for diagnosing the measurement itself but also for accurately monitoring the processes or monitoring and controlling critical operating situations.

www.cpp-net.com search: cpp0116flexim

Thomas Jahn

Thomas Jahn

Head of Operative Marketing, Flexim

Jörg Sacher

Jörg Sacher

Press and Public Relations, Flexim

Share: